Wood has been a foundational material for centuries in construction. While other materials gained prominence in the 20th century, wood is now making a strong comeback. Selecting the right types of wood and lumber is crucial for your building project’s success, durability, and aesthetics. This guide explores diverse types of building wood and lumber, detailing their characteristics and best uses. You will understand various types of building wood and their specific applications. Understanding these types empowers you to make informed, cost-effective, and sustainable choices for all your construction applications.

Key Takeaways

Wood for building comes in two main types: hardwood and softwood. Hardwood is strong and lasts a long time. Softwood grows faster and costs less.

Engineered wood products like plywood and OSB are made from wood parts glued together. They are strong and stable for many building jobs.

Lumber grading tells you about wood quality. It helps you pick the right wood for your project. This ensures your building is strong and looks good.

Pressure-treated lumber has chemicals to stop rot and bugs. It is best for outdoor projects like decks and fences.

Always consider how strong the wood is, how it looks, and if it is good for the environment. This helps you choose the best wood for your building needs.

Fundamental Wood Categories for Construction

When you choose wood for your building needs, you will encounter two main categories: hardwood and softwood. These classifications do not always refer to the actual hardness of the wood. Instead, they describe the tree type from which the wood comes. Understanding these fundamental types of wood helps you make informed decisions for your construction projects.

Hardwood Characteristics and Varieties

Hardwoods come from deciduous trees. These trees lose their leaves in the fall. Hardwood trees grow slower than softwood trees. This slower growth often makes hardwood denser and more durable. You will find hardwood lumber excellent for projects needing strength and longevity. Many hardwood varieties are also beautiful, making them ideal for visible applications.

Common hardwood varieties include oak, maple, ash, and poplar. Oak is a very popular choice. It offers great strength and a distinctive grain pattern. You often see oak in flooring and fine furniture. Maple is another strong hardwood. It has a light color and a fine texture. While generally durable, some maple can be brittle. You can easily work with many types of hardwood. Ash is tough and flexible, often used for tool handles and sports equipment. Poplar is a softer hardwood. You frequently utilize poplar in cabinet-making and painted trim. Hardwood is a premium choice for many construction applications.

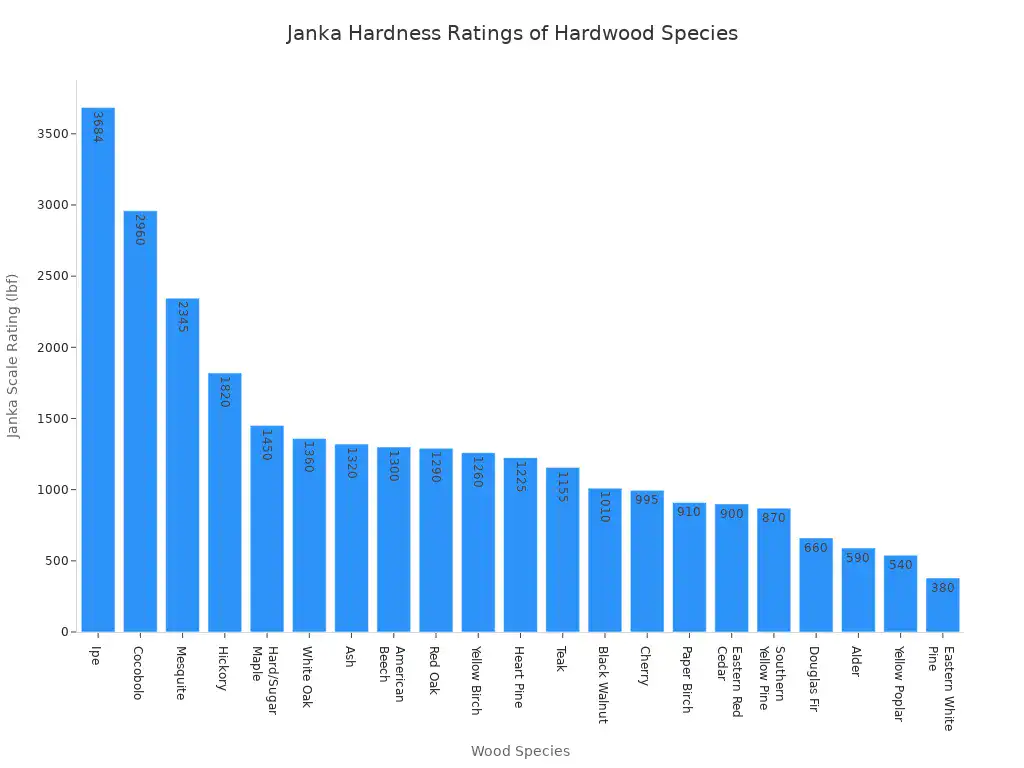

You can see the impressive strength of various hardwoods by looking at their Janka hardness ratings. This rating measures the force needed to embed a steel ball halfway into the wood.

Wood | Janka Scale Rating (lbf) |

|---|---|

Ipe | 3,684 |

Cocobolo | 2,960 |

Mesquite | 2,345 |

Hickory | 1,820 |

Hard/Sugar Maple | 1,450 |

White Oak | 1,360 |

Ash | 1,320 |

American Beech | 1,300 |

Red Oak | 1,290 |

Yellow Birch | 1,260 |

Heart Pine | 1,225 |

Teak | 1,155 |

Black Walnut | 1,010 |

Cherry | 995 |

Paper Birch | 910 |

Eastern Red Cedar | 900 |

Southern Yellow Pine | 870 |

Douglas Fir | 660 |

Alder | 590 |

Yellow Poplar | 540 |

Eastern White Pine | 380 |

Hardwood lumber is excellent for flooring, furniture, and fine woodworking. You will find species like Hard Maple, White Oak, Red Oak, Black Walnut, Ash, Hickory, and Cherry among the best choices.

Softwood Characteristics and Varieties

Softwoods come from coniferous trees. These trees keep their needles year-round. Softwood trees grow faster than hardwood trees. This faster growth makes softwood generally less dense and more flexible. You often choose softwood lumber for general construction and structural framing. Softwood is also more budget-friendly.

Common softwood varieties include pine and cedar. Pine is a very popular and budget-friendly choice. It has a yellow hue. You often use pine in furniture building and general construction. The pine segment holds the largest market share within the softwood market. Cedar is another common softwood. It has a reddish-brown hue. You will find cedar popular for decking, fencing, siding, and trim. Western Red Cedar is naturally resistant to rot and insects. This makes it suitable for outdoor applications. It also has a distinctive scent. Softwood is crucial for many wood-framed construction projects.

Hardwood vs. Softwood Differences

You will notice several key differences between hardwood and softwood. These differences impact their best uses and cost.

Cellular Structure: Hardwoods have a complex cellular structure. They feature tube-like pores (vessels) that transport water and nutrients. These pores create a more prominent and heavier grain. Softwoods have a simpler cellular structure. They move water through longitudinal tracheids and medullary rays. These cells do not form visible pores. Softwoods also produce sap.

Density and Durability: Hardwoods are generally denser and harder. This gives them greater durability. Softwoods are typically less dense. This makes them easier to cut and work with.

Growth Rate: Hardwood trees grow slower. Softwood trees grow faster.

Cost: Softwood lumber is generally more affordable. Hardwood lumber costs more due to its slower growth and greater density.

Consider the typical price differences per board foot:

Wood Type | Typical Price per Board Foot |

|---|---|

Pine (Softwood) | $2.00–$3.50 |

Poplar (Hardwood) | $3.00–$5.00 |

Red Oak (Hardwood) | $4.00–$5.70 |

Ash (Hardwood) | $5.95–$6.50 |

Alder (Hardwood) | Generally under $6.00 |

You can see that softwood, like pine, offers a more economical option for your construction projects. Hardwood, while more expensive, provides superior durability and versatility for specific applications. Both types of building wood play vital roles in wood-framed construction. You choose the right type based on your project’s specific needs, budget, and desired aesthetic.

Engineered Wood Products and Their Uses

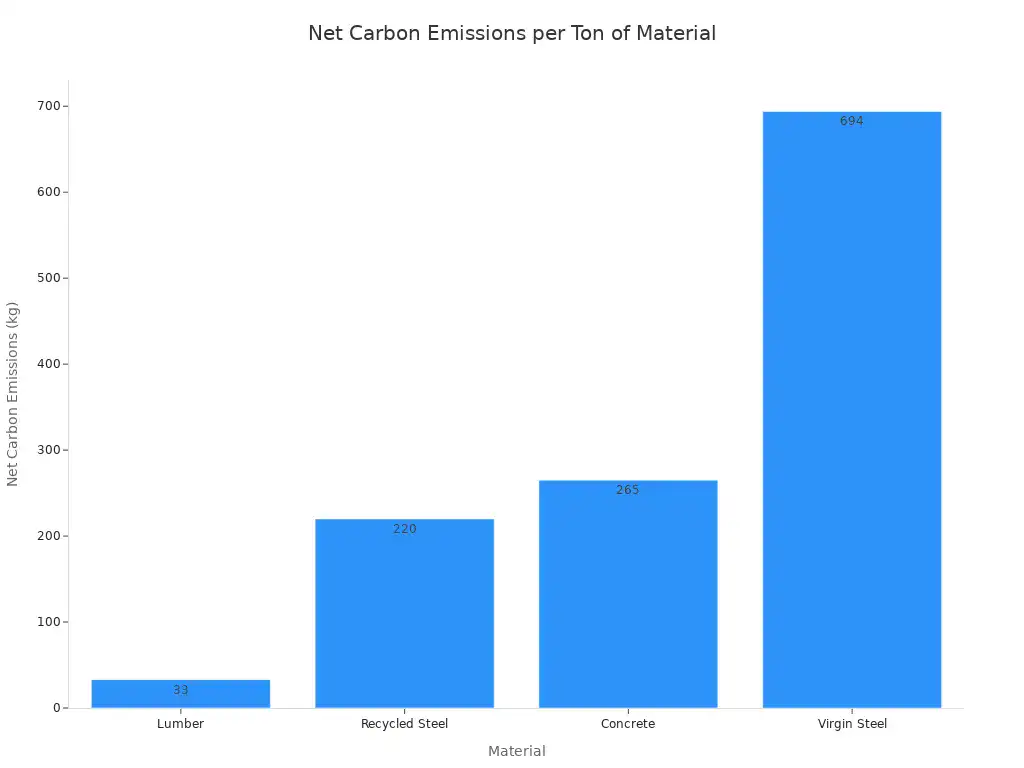

Engineered wood products offer modern solutions for your building needs. Manufacturers create these products by binding together wood fibers, veneers, or strands with adhesives. This process creates materials with enhanced strength, stability, and consistency. You often choose engineered wood for projects demanding high strength and stability. These include floor joists, roof trusses, and structural beams. These types of building wood also provide environmental benefits. Engineered wood has a lower carbon footprint than steel or concrete. It requires less energy to produce. This makes it a better option for reducing carbon emissions in construction. It is a renewable resource. It supports healthy forest regeneration and absorbs more CO₂ from the atmosphere. Engineered wood is less prone to warping than traditional wood. This reduces waste as products last longer. It also utilizes recycled wood materials. These include old scraps, smaller trees, and sawdust. This repurposes them into new products and reduces waste. You will find various types of engineered wood products. Each has its own best uses.

Plywood: Composition and Uses

Plywood is a versatile engineered wood product. It consists of thin wood veneers, or plies, glued together. Manufacturers layer these plies with their grain running in alternating directions. This cross-graining technique gives plywood exceptional strength and resistance to warping. You use plywood in many construction applications. These include sheathing, subflooring, and concrete forms.

Plywood comes in different grades. These grades indicate its appearance and suitability for various applications.

Grade | Characteristics | Structural Applications |

|---|---|---|

Grade A | Smooth, sanded, free of knots/defects; ideal for staining/painting. | Used where appearance is crucial, e.g., cabinetry, furniture, interior paneling. |

Grade B | Smooth surface with minor imperfections; small, tight knots (up to 1 inch); slight discoloration. | Suitable for projects needing good appearance but tolerating minor flaws, e.g., cabinetry, furniture, paneling (painted/covered). |

Grade C | More noticeable defects; larger knots (up to 1.5 inches); limited patches/repairs. | Typically used for structural applications where appearance is not primary, such as subflooring, roofing, and wall sheathing. |

Grade D | Highest number of defects; knots/holes (up to 2.5 inches); common patches/repairs. | Used in construction where appearance is not important, such as subfloors, wall sheathing, and roofing underlayment. |

AA Grade (Premium) | Highest quality, virtually no defects; smooth, sanded; excellent for staining/clear finishes. | Used for high-end cabinetry, furniture, architectural millwork (visible applications). |

AB Grade | High-quality face veneer, lower-grade back; minor defects/knots on back. | Suitable for applications where one side is visible, e.g., cabinet doors, shelving. |

AC Grade | High-quality face veneer, C-grade back; more noticeable defects on back. | Used for projects where one side’s appearance is important, e.g., wall panels, soffits. |

You can see that Grade C and Grade D plywood are common choices for structural lumber applications where appearance does not matter.

OSB: Manufacturing and Uses

Oriented Strand Board (OSB) is another popular engineered wood product. It is created by arranging layers of wood strands in specific orientations. Manufacturers bond these strands with adhesives. They then compress them under high heat and pressure. This process results in a robust, dense, and uniform panel. A key characteristic of OSB is its uniformity. The manufacturing process ensures consistent quality across all panels. This significantly reduces the defects and variations commonly found in natural wood.

The OSB manufacturing process contributes to its structural uniformity through several key steps:

Wood strands are mixed with wax and adhesives.

This mixture is then spread into large mats. Manufacturers carefully orient strands to optimize strength.

They apply high temperature and intense pressure to compress these layers.

The outcome is a solid, consistent board. It is free from knot holes or core voids. This ensures uniform performance.

OSB panels typically consist of three layers of strands. The outer faces feature longer strands aligned in the panel’s long direction. The core layer uses smaller strands that are either counter-aligned or randomly laid. This specific orientation of different layers of aligned strands is crucial for OSB’s unique characteristics. These include enhanced bending strength and stiffness in the oriented direction. The ability to control strand size, orientation, and the layered construction allows manufacturers to engineer OSB for various uses. This ensures consistent properties. You often use OSB as structural lumber for wall sheathing, roof decking, and subflooring. It provides a cost-effective alternative to plywood in many construction projects.

LVL and Glulam

Laminated Veneer Lumber (LVL) and Glued Laminated Timber (Glulam) are high-strength engineered lumber products. They provide excellent alternatives to solid lumber for demanding structural roles.

LVL consists of multiple layers of thin veneers. Manufacturers bond these veneers with adhesives under heat and pressure. All veneers run in the same direction. This gives LVL superior strength and consistency compared to solid lumber. You often use LVL for headers, beams, rim boards, and scaffold planking. It is a reliable form of structural lumber.

Glulam beams consist of several lumber laminations. Manufacturers bond these laminations with durable, moisture-resistant adhesives. The grain of all laminations runs parallel to the length of the beam. This creates large, strong members. Glulam offers superior strength-to-weight ratios. You find glulam beams in many large-span construction projects. These include:

Bridges, skywalks, and porticos.

Commercial, multi-family, and special purpose buildings like arenas and churches. You often choose them over steel due to strength-to-weight ratios and design flexibility.

Auditoriums, airports, and gymnasiums, where they can span up to 500 feet.

Residential, commercial, and public architecture for foundations, floors, cathedral ceilings, and archways.

Artistic pedestrian bridges and heavy-duty industrial buildings.

Glulam is a prime example of engineered lumber for heavy-duty construction.

MDF and Particleboard

Medium-Density Fiberboard (MDF) and Particleboard are composite products. Manufacturers create them from wood fibers or particles. They bond these with resin under heat and pressure. You often use them in cabinetry, furniture, and interior trim.

MDF is denser and stronger than particleboard. It consists of fine fibers. This gives it a smooth surface. You can easily machine and paint MDF. However, MDF does not hold screws very well due to its fine particles. This can lead to stripping of screw holes. For a durable surface on MDF, you should follow specific finishing techniques:

Preparation:

Lightly sand the MDF surface with 220-grit sandpaper. Wipe away dust with a tack cloth. This ensures effective bonding of primer and paint layers. It prevents peeling or chipping.

Seal the edges with a thin layer of glue or specialized MDF sealer. This prevents excessive absorption of paint or primer. It avoids an uneven appearance and reduced durability.

Thoroughly clean the surface with a damp cloth to remove dust and debris. Allow it to dry completely before priming. This ensures proper primer adhesion.

Priming:

Use an oil-based primer, such as a BIN shellac-based primer. Its water-repellency seals the porous MDF surface. It prevents moisture absorption.

Apply primer to edges and inside areas with a brush. Use a roller for larger, flat surfaces for even coverage. Apply two coats. Allow each to dry completely.

Filling and Sanding:

Fill nail holes and imperfections with filler. Overfill slightly and allow it to dry.

Sand the filled areas with 220-grit sandpaper. Blend them smoothly with the surrounding surface. Then wipe away dust.

Painting:

Select a high-quality water-based paint, such as Benjamin Moore Advanced with a semi-gloss finish. This provides a durable and smooth topcoat.

Apply paint to edges and inside areas with a brush. Use a roller for larger, flat surfaces. Apply thin, even coats. Allow each to dry completely. Apply at least two coats for optimal coverage and durability.

Protective Topcoat:

For high-traffic areas, apply a clear polyurethane topcoat. This enhances durability. It resists scratches and protects against wear. Opt for semi-gloss or gloss finishes for easier cleaning and increased resistance to moisture and stains.

Particleboard consists of larger particles. It is less dense and more brittle than MDF. Particleboard has weak screw-holding power. This can lead to hinges and hardware loosening over time, especially in high-use areas. Its softer and more brittle composition means it may not hold up well against nails and screws. It could fall apart. You often choose particleboard for budget-friendly furniture and shelving.

Specific Types of Lumber and Their Best Uses

You will find many forms of processed lumber. Each type has specific grades, dimensions, and optimal applications in construction. Understanding these specific types of lumber helps you choose the right material for your project.

Framing Lumber

Framing lumber forms the skeleton of your building. You use it for walls, floors, and roofs in wood-framed construction. This type of lumber provides structural support. It must be strong and stable. You typically find framing lumber made from softwoods like Douglas Fir, Spruce-Pine-Fir (SPF), Hem-Fir, and Southern Yellow Pine (SYP).

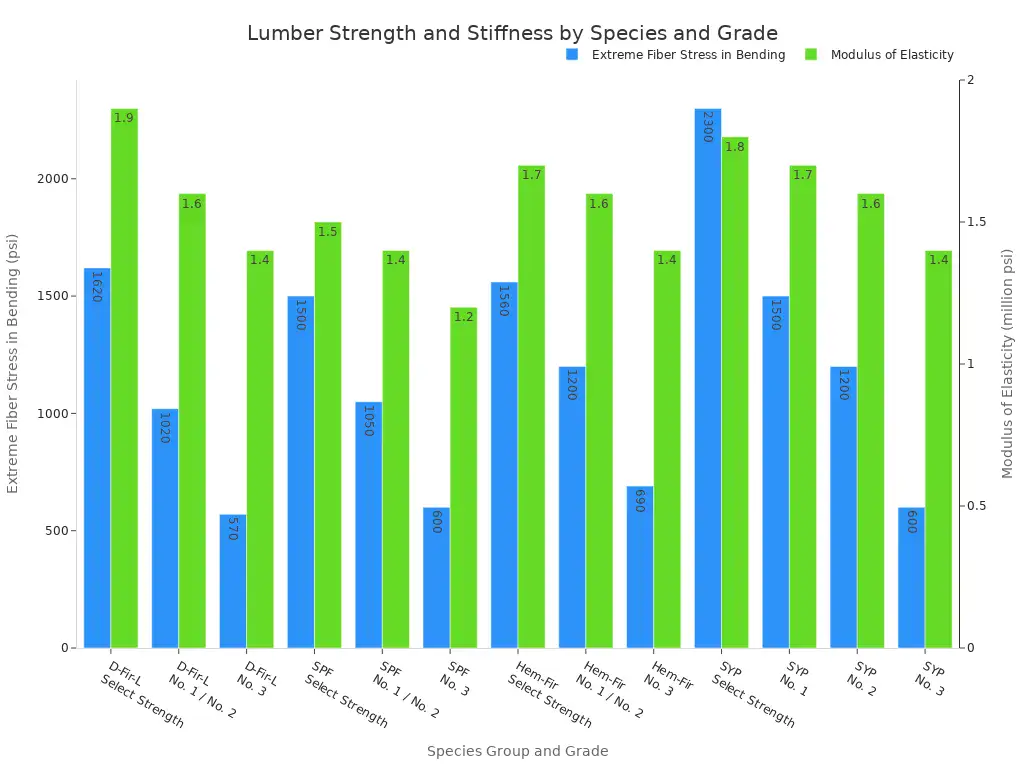

Lumber grades indicate strength and quality. For framing and structural lumber, you often see grades like “No. 1,” “No. 2,” and “Select Structural.” These grades tell you how much load the lumber can bear and how stiff it is.

You can see the strength and stiffness of common framing lumber species in the table below. Extreme Fiber Stress in Bending (Fb) measures strength against loads. Modulus of Elasticity (E) measures stiffness.

Species Group | Grade | Extreme Fiber Stress in Bending (Fb) (psi) | Modulus of Elasticity (million psi) |

|---|---|---|---|

D-Fir-L | Select Strength | 1,620 | 1.9 |

D-Fir-L | No. 1 / No. 2 | 1,020 | 1.6 |

D-Fir-L | No. 3 | 570 | 1.4 |

SPF | Select Strength | 1,500 | 1.5 |

SPF | No. 1 / No. 2 | 1,050 | 1.4 |

SPF | No. 3 | 600 | 1.2 |

Hem-Fir | Select Strength | 1,560 | 1.7 |

Hem-Fir | No. 1 / No. 2 | 1,200 | 1.6 |

Hem-Fir | No. 3 | 690 | 1.4 |

SYP | Select Strength | 2,300 | 1.8 |

SYP | No. 1 | 1,500 | 1.7 |

SYP | No. 2 | 1,200 | 1.6 |

SYP | No. 3 | 600 | 1.4 |

Note: These values are for 2×8 nominal members under normal conditions (moisture content <= 19% placed on edge). Fb measures strength against perpendicular loads, and E measures stiffness (deflection in proportion to load).

You choose higher grades for critical structural lumber applications. Lower grades work for less demanding uses. This ensures your wood-framed construction is safe and durable.

Appearance Lumber

Appearance lumber focuses on visual quality. You use it for projects where the wood will be seen. This includes trim, cabinetry, furniture, and paneling. The grading of this wood prioritizes its look. Clear grades, free from knots, are the highest factor in determining the grade. Other grades depend on the number, size, nature, and presence of knots.

Each piece of lumber goes through an evaluation. This evaluation uses three distinct grades. These grades assess its strength, appearance, and how the wood will function. Selecting the correct grade is essential for both home framing and furniture creation. It ensures your wood products will function as required. This includes meeting both structural and visual appeal needs.

Here are some common appearance grades:

Hardwood Grades:

FAS (First and Seconds): This wood produces at least 83% clear wood. It is ideal for projects needing an elegant, polished finish.

Select grade: This grade ranks just below FAS. It maintains enough clear wood area. It allows minor imperfections.

No. 1 Common: This grade has a minimum board size of 3″ × 4′. It has 66-2/3% clear wood. It is best for furniture parts, kitchen cabinets, and smaller components.

No. 2 Common: This grade has a minimum board size of 3″ × 4′. It has 50% clear wood. It is best for frame components, small wood parts, and rustic designs.

Cedar Lumber Grades (Western Red, Alaskan Yellow, and Other Cedar):

Clear Vertical Grain (CVG): This is the best grade for visual applications. You use it for paneling, siding, trim, cabinets, and soffits.

A & Better Clear: This grade suits appearance applications. Finishing requirements are less exact.

C & Better Clear: This grade is mostly clear. It may have unimportant characteristics. These include color changes, small pitch streaks, and small knots.

D & Better Clear: This grade will have medium pitch streaks. It has occasional small knots. It shows more visual imperfections than higher grades.

Select Tight Knot (STK): This grade features knots, burls, and natural markings. These add decorative character.

Douglas Fir Boards & Timbers Lumber Grades:

Clear Vertical Grain (CVG): This is the top quality grade for a superior appearance.

D & Better: This is an appearance grade. You use it for paneling applications.

Select Deck: This is the lowest grade for Douglas Fir boards. You intend it for exposed uses. These include paneling, shelving, and other applications needing a knotty appearance.

Specialized grading also includes color sorting. This ensures visual uniformity for products where color consistency is paramount. These products include furniture, flooring, and architectural millwork. Defect categorization distinguishes between defects you can work around and those that pose genuine challenges. This maximizes usable material.

Pressure-Treated Lumber

Pressure-treated lumber undergoes a process. Manufacturers force chemical preservatives into the wood fibers. This process protects the wood from rot, fungi, and insect attacks. You use pressure-treated lumber for outdoor applications. These include decks, fences, and playground equipment. It is also common for sill plates in new construction. It prevents rot and insect infestation.

Working with pressure-treated lumber requires specific safety precautions. You must protect yourself from the chemicals.

Wear long sleeves and long pants. This prevents sawdust and chips from touching your skin. It reduces exposure to preservative chemicals. Wash these clothes separately.

Wear gloves to protect your hands. This prevents exposure to preservative chemicals. Treated wood is often wet. Sturdy leather work gloves are recommended. Always wash your hands after handling.

Use a dust mask when cutting or sanding. This prevents inhaling sawdust. This is especially important with pressure-treated wood.

Cut and sand outdoors. This prevents sawdust from settling on indoor surfaces. It allows sawdust to blow away. Ideally, stay upwind.

Dispose of sawdust, chips, and scraps properly. Sweep them up, bag them, and send them to a municipal landfill. Never use pressure-treated sawdust as mulch. Do not burn scraps.

Wear eye protection when working with pressure-treated wood. Sawdust can irritate your nose, eyes, and skin. Prevent skin contact as much as possible.

Collect sawdust for disposal. Cut in a designated area with a disposable plastic tarp underneath.

Do not burn pressure-treated wood. The ash is highly toxic due to its chemical content. Only professionals should burn it.

Avoid using pressure-treated wood for cutting boards or food preparation surfaces. Picnic tables made of this wood are suitable for serving food, not preparing it. You should coat them with an oil-based wood preservative to seal in chemicals.

Do not use pressure-treated wood where it might contact drinking water. Incidental contact, like fresh water docks, is an exception.

Avoid using pressure-treated wood where its preservative might become part of food, animal feed, or beehives.

Clean up and dispose of all sawdust and debris after construction.

Dispose of pressure-treated wood in landfills or commercial/industrial incinerators. Follow local regulations.

Decking and Siding

You need durable wood for decking and siding. These materials face constant exposure to weather elements. Choosing the right lumber types reduces maintenance. Regular care extends their life and improves their appearance.

Consider these general points for outdoor wood:

Protect furnishings from direct rain, snow, and sunshine. This extends their usefulness. UV rays break down all woods. Excessive moisture promotes fungi, mold, and insects.

Keep a moisture barrier between wood furniture and the ground. This prevents water wicking.

Avoid artificial drying with heat or forced air. Rapid changes cause uneven shrinking and cracks.

Bringing wood furniture indoors for winter is ideal. It prevents damage from melting snow and freeze/thaw cycles.

Do not drape wood with plastic. Dew can form underneath and prevent drying. Canvas keeps furniture soggy.

A waterproof topcoat, like Le Tonkinois, extends the life of furnishings. This is true even without UV inhibitors.

Heartwood is recommended over sapwood for outdoor projects. It offers strength and blocks moisture and insects.

For maximum moisture protection, even water-resistant wood types benefit from a finish. The choice depends on indoor or outdoor use. For outdoor wood, choose finishes that penetrate the surface for long-lasting protection. Avoid film-forming ones.

Recommended Owatrol products for outdoor use include:

Owatrol Seasonite: This product is for wood’s first year. It prevents moisture damage. It prepares the wood for recoating after 6-12 months.

Owatrol H4 Wood: This is a clear, hydrophobic finish. It seals wood from water. It allows natural weathering to a silvery-grey. It prevents splitting, cracking, and warping.

Owatrol Textrol HES: This is a powerful, penetrating oil-based sealant. It is available in various shades for a matt-sheen finish.

Owatrol Aquadecks: This is a penetrating, water-based finish. It provides long-lasting moisture protection. It saturates and stabilizes wood. It suits new or weathered wood. It is available in tints with a rich, matt finish.

You can apply these products with a brush, roller, or airless sprayer. Brushing is recommended for best results. Reapplication timelines vary. They are typically every couple of years. This depends on exposure to water, sun, and salt spray.

Here are specific wood species for decking and fencing lumber:

Acacia: This is a thick, strong hardwood. It has high oil content. It resists elements, rotting, and insects. It is abundant and affordable. James Armstrong notes its durability and resistance to elements. You often use it in boat-building. It needs sealing to prevent discoloration if regularly exposed to water. Keep it off grass or the ground to avoid moisture absorption.

Black Locust: This is one of the strongest and stiffest domestic woods. It has excellent stability and rot resistance. It is durable with good weathering characteristics. Jacob Aune highlights its exceptional strength and decay resistance. This makes it suitable for structural outdoor applications. It outperforms white oak in longevity.

Cedar: This wood is soft, light, and easy to work with. It has poor screw-holding capabilities. It resists rot, termites, and Powder Beetles. Native North American cedars offer excellent resistance to rot and most insects. It can last years without maintenance. Treatment enhances its lifetime. It weathers to a gray color if untreated. It is softer and faster-growing than hardwoods, so it will not last as long.

White Oak: Jacob Aune’s favorite for furniture. It offers strength, hardness, and suitability for indoor or outdoor use. It is abundant and available in various sizes. It resists rot and is easy to work with. Armstrong states that regularly stained and well-maintained white oak can last decades. You widely use it in boat-making and barrel-making. This is due to its waterproof characteristics. Tyloses prevent water penetration. It requires painting or a water-resistant sealer or topcoat. It lacks natural oils like teak or ipe. However, it offers significant cost savings. Avoid red oak due to its porosity.

You choose the best uses for these types of lumber based on your project’s needs.

Wood Selection Considerations

You must consider several factors when you choose wood for your projects. These considerations ensure you select the best material for your needs. They also help you make responsible choices.

Lumber Grading and Standards

Lumber grading assesses wood quality, strength, and appearance. Trained inspectors use standard criteria. They look at knots, grain patterns, and defects. This classification ensures lumber meets industry standards. It helps you use it correctly in construction. For hardwoods, grading focuses on aesthetic qualities. It looks at the percentage of clear wood you can get. Higher grades mean more usable material. For softwoods, grading often focuses on structural integrity. This is important for load-bearing projects. Grading considers the size and number of defects.

Common Wood Defects

You might encounter common defects in wood. Warping and checking are two examples. Wood absorbs moisture from the air. It also dries out too quickly. This causes warping. Uneven drying leads to twisting or bending. Rapid moisture loss from outer layers causes surface cracks. You call these end-checking. Inconsistent storage conditions also create uneven drying. This affects the wood’s stability.

Wood Measurements and Dimensions

You need to understand wood measurements. Nominal lumber dimensions are the size before drying and planing. Actual lumber dimensions are the finished size. Nominal measurements are larger than actual measurements. The difference varies. Moisture content, shrinkage, and surfacing techniques affect the final size.

Nominal Size | Actual Size |

|---|---|

1 x 2 | ¾ x 1 ½ |

1 x 4 | ¾ x 3 ½ |

1 x 6 | ¾ x 5 ½ |

2 x 4 | 1 ½ x 3 ½ |

2 x 6 | 1 ½ x 5 ½ |

2 x 8 | 1 ½ x 7 ½ |

Stores often label lumber with nominal dimensions. They must also state the actual measurements.

Sustainability and Environmental Impact

You can make environmentally friendly choices. Look for certifications like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). These ensure sustainable harvesting. Wood offers climate benefits. It stores carbon. It substitutes materials with higher emissions.

Lumber has low net carbon emissions per production ton. It is much lower than concrete or steel. Wood is about 50% carbon by dry weight. It stores carbon for the life of a structure. You should source from certified suppliers. Verify their certificates. For treated wood, never burn it. Its ash is toxic. Check with your local waste management for disposal rules. This ensures environmental stability.

You now understand the vast array of wood and lumber options for building. Selecting the right types of wood is crucial. We discussed hardwoods, softwoods, engineered wood, and specific lumber types. Each offers unique strengths. The best uses for any wood depend on your project’s needs, budget, and desired look. Always consider durability, structural requirements, appearance, and environmental factors. You can confidently choose the right wood for your next building endeavor.

FAQ

What is the main difference between hardwood and softwood?

Hardwood comes from deciduous trees that lose leaves annually. It is generally denser and more durable. Softwood comes from coniferous trees that keep needles year-round. It grows faster and is typically less dense. You choose each type of wood based on your project’s needs.

What are engineered wood products?

Engineered wood products are materials made by binding wood fibers, veneers, or strands with adhesives. This process creates products with enhanced strength and stability. You use them for structural components like beams and joists. They offer consistent quality and reduce waste.

What does “lumber grading” mean?

Lumber grading assesses the quality, strength, and appearance of wood. Inspectors examine knots, grain patterns, and defects. This process ensures the lumber meets industry standards. It helps you select the right wood for specific construction uses.

What is pressure-treated lumber used for?

Pressure-treated lumber has chemical preservatives forced into its fibers. This protects the wood from rot, fungi, and insects. You use it for outdoor projects like decks, fences, and playground equipment. It provides durability in harsh environments.

Why are actual lumber dimensions different from nominal dimensions?

Nominal dimensions are the size of the wood before drying and planing. Actual dimensions are the finished size. The difference comes from moisture loss, shrinkage, and the milling process. For example, a “2×4” piece of lumber actually measures 1 ½ x 3 ½ inches.