Many people believe all screws for wood are interchangeable. However, a critical distinction exists between different types of screws. Construction screws provide structural integrity and handle heavy loads. Wood screws connect lighter, non-structural wood-to-wood pieces. Understanding these differences ensures project success, safety, and longevity. The U.S. construction industry experiences billions of dollars in annual losses from fastener-related failures. Choosing the correct type of screws prevents such costly mistakes.

Key Takeaways

Construction screws are strong. They hold heavy things. They are for building parts that carry weight, like decks.

Wood screws are for lighter jobs. They connect wood pieces that do not carry heavy weight, like furniture.

Using the wrong screw can cause problems. It can make things break or fall apart. Always pick the right screw for the job.

Construction screws have special coatings. These coatings stop rust. This helps them last a long time outside.

Always use pilot holes for screws. This stops the wood from splitting. It helps the screw go in straight.

Understanding Construction Screws

Construction screws are heavy-duty fasteners. They provide structural support and handle significant loads. These screws offer toughness, strength, and durability. They surpass standard wood screws in demanding applications.

Construction Screw Characteristics

Construction screws have distinct physical characteristics. They feature a thicker shank, often ranging from 3/16 to 5/16 inches or larger. This thicker shank provides greater strength and resistance to shear forces. Their threads are coarse with a relatively large pitch. This design allows for quick penetration into hard materials. Common head types include flat heads for flush surfaces, hex heads for high-torque installation, and bugle heads for easy countersinking. These are some of the defining characteristics of construction screws.

Materials and Coatings

Manufacturers make construction screws from high-strength steel alloys. Sometimes they use stainless steel. Hardened steel offers exceptional tensile strength. This makes it suitable for framing and load-bearing applications. Stainless steel provides moderate corrosion resistance for indoor use. However, it is slightly less strong than hardened steel. Various coatings enhance performance. Zinc plating offers basic corrosion protection. Hot-dipped galvanizing provides durable outdoor use. Epoxy coatings give additional corrosion resistance and improved grip. Many exterior screws feature these advanced coatings.

Coating Type | Description | Effectiveness/Key Features |

|---|---|---|

Zinc (Electrogalvanized) | Thinner zinc layer applied via electro-plating. | More economical, but more prone to rust over time due to thinner layer. |

Zinc (Hot-Dipped) | Thicker zinc layer applied via hot dipping. | Resists corrosion longer than electrogalvanized, but coating can be uneven. |

Epoxy Coatings | Polymer-based, often applied over electrogalvanized metal. | Provides even corrosion protection, can be color-matched, expected to last the usable life of the project. |

PrimeGuard® | Proprietary coating with electroplated zinc base and epoxy resin top coat. | Guaranteed for up to 10 years, robust protection, ideal for treated wood. Endures minimum 750 hours in ASTM B117 salt spray test. |

PrimeGuard PLUS® | Similar to PrimeGuard® with more extensive testing. | Lasts the life of the project for outdoor applications like fencing, siding, decking. Endures minimum 1000 hours in ASTM B117 salt spray test. |

PrimeGuard® Nano | Electroplated zinc base with organic top coats. | Most robust protection, guaranteed for lifetime of project when installed properly. Not rated for cedar or around pools. Endures minimum 1000 hours in ASTM B117 salt spray test. |

These coatings are crucial for exterior screws. They protect against environmental factors.

Thread Design

Construction screws have specific thread designs. These designs maximize holding power. Jordan Smith explains, “As they thread their way through the fibers, instead of pushing them out, they’re sneaking in between them. When I try to pull it out, now I have fiber sitting directly on top of this thread.” This design creates a strong grip. Different types of construction screws have varied thread patterns. For example, concrete screws have a double thread. One thread cuts, and the other holds. Drywall screws have coarse threads for wood supports. These specialized threads ensure optimal performance for various applications.

Head Types and Drives

Construction screws come with various head types and drive systems. These features suit different installation needs.

Head Type | Description | Common Uses |

|---|---|---|

Bugle | Countersunk with a curved taper and flat top | Soft materials like drywall and wood – helps prevent splitting and provides a flush finish |

Flat | Countersunk with straight standard angles and a flat head | Applications that require flush finishes for minimal interference |

Hex | Six-sided flat head, sometimes indented | Industrial equipment and construction applications, often in thin materials |

Hex Flange | Similar to the hex head but with a washer-like flange at the base | Where larger bearing surface is needed to protect mating surface and distribute the load |

Truss | Similar to a round head but with a shorter top and a wider base | Where a low-profile decorative finish is required – provides a larger bearing surface |

Modified Truss | Similar to a truss head but with a wider, washer-like base | In settings like the standard truss but where a lower profile is necessary |

Wafer | Countersunk and similar to a bugle head but with a wider, washer-like flat top | Soft materials that need to resist splitting but also require a larger bearing surface |

Screw drive types determine the required installation tool. They also facilitate different levels of torque. Historically, screws had slots and square heads. The Industrial Revolution led to drives with better cam-out resistance. This resulted in the variety seen today.

Shank and Shear Strength

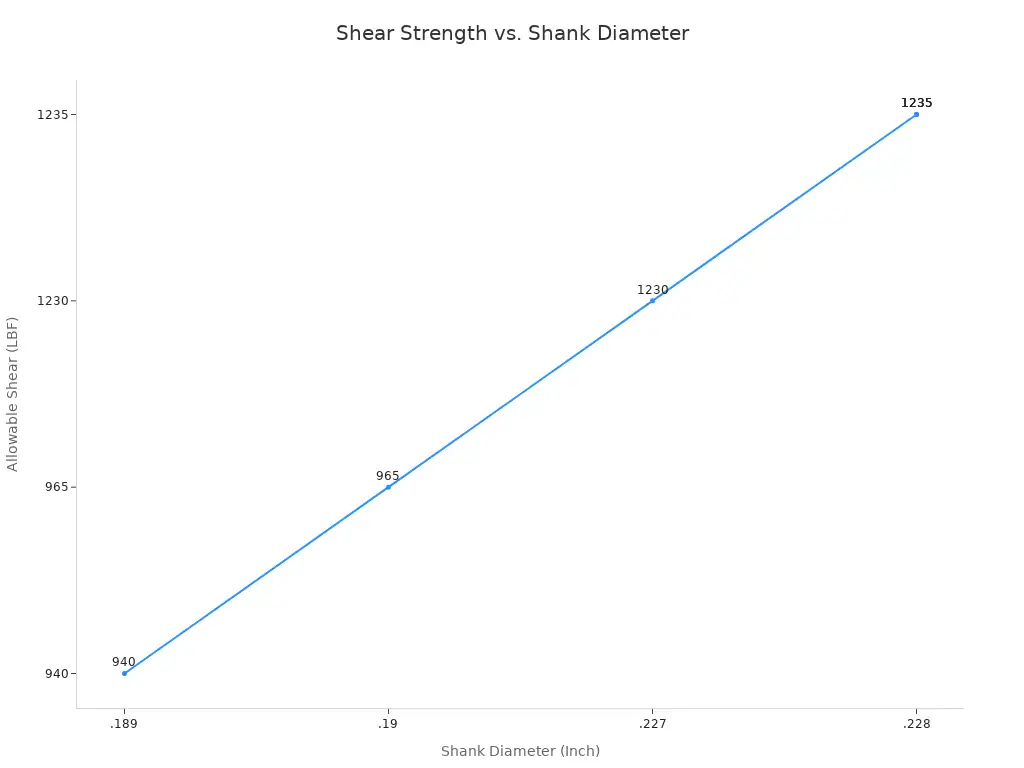

The shank diameter of a construction screw directly influences its shear strength. A larger unthreaded shank diameter generally correlates with higher allowable shear strength. This is critical for load-bearing applications.

The chart illustrates this relationship. For example, screws like FlatLOK and LedgerLOK have larger shank diameters. They also exhibit higher allowable shear forces. This makes them suitable for heavy-duty structural connections. Different types of construction screws offer varying shear strengths. This depends on their design and material.

Understanding Wood Screws

Wood screws connect pieces of wood in non-structural applications. These fasteners primarily join wood to wood. They have a sharp point and coarse threads. This design helps them grip wood fibers effectively. Understanding the different types of wood screws helps in choosing the right one for a project.

Wood Screw Characteristics

Wood screws have specific characteristics. Their diameter, also known as gauge, determines the width of the screw. A smaller gauge number means a larger screw diameter. Gauges typically range from #0 for delicate work to #20 for heavier tasks. Length is another key characteristic. It measures from the material’s surface to the screw’s point. Flat-head wood screws include the head in their length measurement. Round or oval head wood screws measure from directly under the head to the point. Many types of wood screws feature a flat head. They also have a sharp point for easy wood penetration. Cutting threads allow the screw to create its own path in the wood. This often eliminates the need for pre-drilling.

Traditional Wood Screw Design

Traditional wood screws evolved over time. Early hand-made screws had irregular threads and blunt ends. Later manufacturing methods improved consistency.

Era/Method | Design Elements |

|---|---|

Early Hand-made | Irregular thread spacing and shape, file marks on head and between threads, often blunt end. |

Late 1700s (Cutting Dies) | More uniform threads than purely hand-made, but still distinct from later methods. |

1760s (Lathe Manufactured) | Improved uniformity over earlier methods. |

1850s (Swaging Tools) | More uniform and consistent threads, rounded valleys with sharp and rough threads. |

Machine-produced (Cut Wood Screws) | Almost invariably tapered, threads do not extend past the shank diameter. |

These design changes led to more reliable wood screws.

Threading for Wood

Wood screws feature thread profiles optimized for gripping wood fibers. These designs also help prevent splitting. Spax screws have uniquely serrated threads. They chew up wood fibers and auger them out. This provides clearance for the screw shaft. It virtually eliminates splitting, even in hard wood. GRK screws use a fluted tip and notched threads. The tip severs fibers, and the notched threads help excavate chips. Coated deck screws have a fluted tip. This tip bores a pilot hole. While they reduce splitting, the tip cuts fibers without effectively excavating chips. Different types of wood screws offer varied threading benefits.

Head Styles and Aesthetics

Wood screws come in various head styles. These styles serve both functional and aesthetic purposes. Flat heads sit flush with the wood surface. Round heads remain visible and offer a decorative look. Oval heads provide a slightly raised, finished appearance. The choice of head style depends on the project’s needs and desired finish.

Material and Finish

Manufacturers make wood screws from various materials. They also apply different finishes. Aluminum screws are strong and prevent corrosion when assembling aluminum parts. Solid brass screws are soft. They require careful pilot holes. These screws are ideal for installing solid brass hardware. Silicon bronze screws suit marine boat building. They also work well for cedar or redwood decks. Dry-lube hardened steel screws are popular for interior use. They reduce driving torque. However, they offer little corrosion resistance. Stainless steel screws provide excellent corrosion resistance. They are softer than hardened steel. Black finish screws, like black phosphate coatings, offer corrosion resistance and a foundation for painting. Steel screws are common for woodworking and interior DIY projects. They are strong and affordable. Stainless steel screws resist rust and corrosion. Silicon bronze screws also offer good resistance to rust and corrosion. Finishes like bright zinc plating offer minimal corrosion resistance. Black oxide plating prevents rust staining. Galvanizing provides good rust protection. Specialized coatings, such as Blue-Kote™ or Climatek™, offer enhanced corrosion resistance for outdoor use. Wax coatings reduce friction. These coatings make screws easier to drive.

Comparing Construction and Wood Screws

Choosing the right fastener is crucial for any project. Construction screws and wood screws serve different purposes. They have distinct designs. Understanding these differences helps ensure project success and safety.

Strength and Load Bearing

Construction screws are heavy-duty fasteners. They are specifically engineered and tested for load-bearing connections. These screws typically feature higher shear and tensile strength ratings. This makes them suitable for structural applications. Structural screws, a type of construction screw, possess high tensile and shear strength. They are designed for load-bearing applications. Regular wood screws, however, are suitable for lighter-duty jobs. They have lower strength. They are not designed for structural loads or dynamic movement.

Construction screws are manufactured from heavy-duty materials. These materials include high-carbon steel, stainless steel, and other alloys. Engineers design them to withstand shear forces. These forces are significantly greater than those handled by conventional screws. This creates robust and reliable connections. These connections are in materials subjected to shear and load forces. Their larger gauge and aggressive threads prevent shearing off or pulling out under stress. Many also feature a wide load-bearing surface. This reduces pull-through. Using regular wood screws in structural applications can lead to premature failure. This is especially true when subjected to tension or shear loads. Construction screws are specifically designed for load-bearing elements. Examples include decks, pergolas, and ledger boards. They ensure safety and longevity.

Feature | Structural Screws | Regular Wood Screws |

|---|---|---|

Load Rating | High (structural rated) | Low (non-structural) |

Use Case | Framing, decks, beams (load-bearing) | Trim, panels, cabinetry (non-load-bearing) |

Strength | High tensile and shear strength | Lower strength, not designed for structural loads |

Compliance | Code-compliant (e.g., ICC-ES, AC233 rated) | Not typically rated for structural performance |

Thread Aggressiveness

Construction screws often feature more aggressive threads. These threads provide superior grip in dense materials. They are designed to cut through wood fibers. This creates a strong, secure connection. Some construction screws have specialized thread designs. These designs include serrated threads or fluted tips. These features help reduce splitting and improve driving ease. Wood screws have coarse threads. These threads are designed to grip wood fibers effectively. They create their own path in the wood. This often eliminates the need for pre-drilling in softer woods. Their threads are less aggressive than those on many construction screws. This makes them ideal for joining wood pieces without causing excessive damage.

Material and Corrosion Resistance

Manufacturers make construction screws from high-strength steel alloys. These materials provide the necessary durability for structural applications. They often come with advanced coatings. These coatings include hot-dipped galvanizing or epoxy finishes. These coatings offer superior corrosion resistance. This is essential for outdoor or exposed projects. Wood screws come in various materials. These include steel, brass, and stainless steel. Steel wood screws are common for interior use. They are strong and affordable. Stainless steel wood screws provide excellent corrosion resistance. They are suitable for outdoor or marine environments. Finishes like zinc plating offer basic protection. Specialized coatings enhance resistance for specific applications.

Shank Diameter and Shear

Construction screws typically have a larger shank diameter. This thicker shank directly contributes to higher shear strength. Shear strength is the ability of a fastener to resist forces that try to cut it in half. A larger unthreaded shank diameter generally correlates with higher allowable shear strength. This is critical for applications where the fastener supports significant weight or experiences lateral forces. Wood screws generally have a smaller shank diameter. This makes them less resistant to shear forces. Their design prioritizes holding power within the wood fibers. It does not focus on resisting heavy cutting forces.

Installation Needs

Installing construction screws often requires more power. They have thicker shanks and aggressive threads. This means installers typically use power drills or impact drivers. Pilot holes are often necessary. This prevents splitting in dense materials. It also ensures proper seating. Wood screws are generally easier to install. Many can be driven with a hand screwdriver. Power drills also work well. Pilot holes are beneficial for wood screws. They prevent splitting, especially in hardwoods or near edges. However, some modern wood screws have self-drilling tips. These tips reduce the need for pilot holes.

Cost Considerations

Construction screws are generally more expensive than wood screws. Their specialized materials, advanced coatings, and rigorous testing contribute to the higher cost. The investment in construction screws reflects their critical role in structural integrity and safety. Wood screws are more affordable. They are suitable for a wider range of non-structural applications. The cost difference often reflects the performance and safety requirements of the intended use.

When to Use Construction Screws

Construction screws are essential for projects demanding high strength and durability. They provide critical structural integrity. Understanding specific construction screw uses helps ensure safety and longevity in various applications.

Structural Framing

Builders use construction screws extensively in structural framing. These fasteners create strong, reliable connections in load-bearing structures. For example, they secure roof trusses, wall studs, and floor joists. CAMO structural screws are independently tested and certified as IBC and IRC code-compliant by DrJ Engineering. This certification ensures they meet strict building standards. The International Code Council Evaluation Service (ICC-ES) evaluates proprietary screw designs for structural applications. They use criteria like AC233 for dowel-type threaded fasteners in wood. The American Wood Council (AWC) National Design Specification for Wood Construction® (NDS) also includes provisions for these standard screw types. These regulations highlight the importance of using appropriate construction screws for structural integrity.

Outdoor Projects

Outdoor projects require fasteners that resist weather and corrosion. Construction screws designed for exterior use offer superior protection. These exterior screws withstand moisture, temperature changes, and UV exposure.

Screw Type | Recommended Use | Reason for Recommendation |

|---|---|---|

Stainless Steel Screws | Decks, fences, docks, outdoor furniture, marine applications, areas with high moisture or salt exposure. | Excellent corrosion resistance, especially in harsh environments. Available in various grades (e.g., 304 for general outdoor use, 316 for saltwater). |

Galvanized Screws | Fences, decks, general outdoor construction where some corrosion resistance is needed but stainless steel is too costly. | Coated with a layer of zinc for corrosion protection. Hot-dip galvanized offers better protection than electro-galvanized. |

Ceramic Coated Screws | Decks, fences, general outdoor construction, treated lumber. | Offer good corrosion resistance and often have a lubricated coating for easier driving. Compatible with ACQ-treated lumber. |

Polymer Coated Screws | Decks, fences, siding, trim, general outdoor use. | Provide good corrosion resistance and often come in colors to match decking or siding. Good for treated lumber. |

Silicon Bronze Screws | Marine applications, boat building, high-end outdoor furniture, historical restorations. | Excellent corrosion resistance, especially in saltwater. Aesthetically pleasing, but more expensive. |

Deck Screws | Decking, outdoor stairs, railings. | Specifically designed for deck construction, often featuring self-drilling tips, coarse threads for strong grip, and corrosion-resistant coatings. |

Lag Screws (Lag Bolts) | Heavy-duty outdoor applications like attaching ledger boards, timber framing, playground equipment. | Large, heavy-duty screws with hex heads for high torque. Often galvanized or coated for outdoor use. |

Concrete Screws (Tapcons) | Attaching wood or metal to concrete or masonry outdoors. | Designed to cut their own threads into pre-drilled holes in concrete. Available with corrosion-resistant coatings for outdoor exposure. |

Self-Drilling Screws (Tek Screws) | Attaching metal to metal outdoors, often in roofing or siding. | Have a drill bit-like tip that drills its own pilot hole. Available with corrosion-resistant coatings. |

Wood Screws (Exterior Grade) | General outdoor woodworking, attaching trim, small outdoor projects. | Traditional wood screws made from corrosion-resistant materials or with protective coatings. |

Timber Screws | Large timber construction, landscaping, retaining walls. | Heavy-duty structural screws designed for joining large timbers, often replacing lag screws. Feature advanced coatings for outdoor durability. |

Gutter Screws | Attaching gutters to fascia boards. | Often made of aluminum or stainless steel to resist corrosion from water. |

Roofing Screws | Attaching roofing materials (metal, asphalt shingles) to roof decking. | Designed with a washer to seal against water penetration and often have corrosion-resistant coatings. |

Fence Screws | Attaching fence pickets, rails, and posts. | Typically galvanized or coated for weather resistance, designed for wood or vinyl fencing. |

Landscape Screws | Securing landscape timbers, edging, and other outdoor landscape features. | Long, heavy-duty screws with corrosion-resistant coatings, designed for treated lumber and ground contact. |

Stainless Steel Trim Screws | Attaching exterior trim, fascia, soffits. | Small diameter, often with a small head for a discreet finish, made from stainless steel for corrosion resistance. |

Composite Deck Screws | Attaching composite or PVC decking. | Designed to prevent mushrooming and cracking in composite materials, often color-matched and corrosion-resistant. |

Pole Barn Screws | Attaching metal siding and roofing to pole barn structures. | Feature a washer for sealing and corrosion-resistant coatings, designed for exterior exposure. |

Marine Grade Screws | Boats, docks, piers, saltwater environments. | Made from high-grade stainless steel (316) or silicon bronze for superior saltwater corrosion resistance. |

Exterior Wood Screws | General outdoor wood construction, furniture, planters. | A broad category of screws specifically designed for outdoor use, featuring corrosion-resistant materials or coatings. |

These specialized exterior screws ensure the longevity of outdoor structures.

Heavy-Duty Fastening

Construction screws are crucial for heavy-duty fastening applications. They provide the necessary strength for demanding tasks.

Deck Framing: HeadLOK, VersaLOK, and LedgerLOK are used for exterior deck framing. LedgerLOK specifically fastens deck ledger boards to rim joists.

Multi-ply Wood Connections: FlatLOK connects various multi-ply dimensional and engineered wood. This includes multi-ply roof girder trusses and LVL beams.

Structural Framing: FrameFAST is a heavy-duty framing screw. It secures roof trusses, wall studs, plates, and deck joists to carrying beams.

General Carpentry and Remodeling: MVP, TimberLOK, HeadLOK, and VersaLOK suit general carpentry, interior remodeling, and other structural applications.

Through-Bolted Connections: ThruLOK combines the strength of a through-bolted connection with the speed of a LOK fastener. It connects deck posts to joists, notched posts to beams, and multi-ply beams. Other heavy-duty fasteners include:

Threaded Rods: These are primarily used for installing drop ceilings in new buildings. They withstand intense tension and vibration.

Structural Hex Bolts: These have a larger head and shorter thread length. They are typically used for structural connections in buildings and bridges.

Specialty Screws: These are designed for unique functions. They include heavy-duty lifting ring bolts for lifting large equipment.

Subfloor and Sheathing

Construction screws are highly effective for subfloor and sheathing installations. They offer superior holding power. Their threaded design ensures a tighter grip. Code-approved screws are recommended for these applications. Fasteners should be placed every 6 inches along panel edges. They should be placed every 12 inches in the field. Always check local building codes for exact requirements. Unlike nails or staples, screws resist loosening over time. This makes them ideal for strong, lasting connections. Their ability to be easily removed and replaced also suits projects needing future adjustments.

Specific types of screws excel in subfloor applications:

SubLoc Pro Scrail Fasteners: These hybrid fasteners combine a nail’s versatility with a screw’s holding strength. They drive faster than traditional screws using most framing nailers. Workers can adjust or remove them after placement. Their aggressive threading and diamond coating provide exceptional holding power. They virtually eliminate floor squeaks.

Paslode’s TetraGRIP Subfloor Fastener: This fastener features a barbed thread design. It bonds with wood fibers without causing destruction. This is described as ‘rotation without destruction.’ General screws prevent creaking floors. They firmly hold the subfloor in place. This ensures a squeak-less floor for years. They offer more overall holding power than ring shank nails. This is due to their larger threads gripping a bigger surface area. This keeps the subfloor very tight and prevents shifting or loosening.

Deck Screws for Outdoor Use

Deck screws are a specialized type of construction screw. They are specifically designed for outdoor deck construction. These screws must withstand harsh outdoor conditions.

Feature/Material | Description/Best For | Considerations |

|---|---|---|

Corrosion-resistant finishes | Designed for weather exposure and treated lumber. | Essential for outdoor durability. |

Deep, aggressive threads | Provides lasting hold as boards expand and contract. | Prevents board movement. |

Sharp/self-tapping points | Allows quick starting and reduces splitting, especially near board ends. | Improves installation efficiency and board integrity. |

Modern drive types (e.g., 6-lobe/TORX®) | Reduces cam-out compared to Phillips head screws. | Enhances driving stability and reduces stripping. |

Polymer-coated carbon steel | General outdoor use, pressure-treated lumber. | Coating quality varies; choose tested finishes. |

Hot-dip galvanized | Treated lumber; rugged builds. | Thicker coating; pre-drilling may be needed. |

Stainless (A2 / 304) | High corrosion resistance in inland areas. | Softer than carbon steel; higher price. |

Stainless (A4 / 316) | Coastal and marine exposure. | Highest cost due to superior corrosion resistance. |

Choosing the correct length of deck screws is also important.

Decking Thickness | Recommended Screw Length | Notes |

|---|---|---|

5/4″ (≈1″ nominal) | 2-1/2″ | Common for wood and many composites. |

2″ nominal | 3″ | For heavier boards; verify joist spacing. |

Dense hardwoods | 2-1/2″–3″ | Pre-drill to minimize splits and snapping. |

These features ensure deck screws provide a secure and lasting connection for deck boards. Proper deck screws prevent common issues like board warping and loosening.

When to Use Wood Screws

Wood screws connect pieces of wood in non-structural applications. These fasteners primarily join wood to wood. They have a sharp point and coarse threads. This design helps them grip wood fibers effectively. Understanding the different types of wood screws helps in choosing the right one for a project. This section explores various wood screw uses.

Furniture Assembly

Wood screws are ideal for assembling furniture. They create strong, yet often removable, connections. Builders use them for cabinets, tables, and chairs. Their design allows for a secure hold without damaging the wood.

Decorative Woodworking

Wood screws also enhance decorative woodworking projects. They offer both functionality and aesthetic appeal.

Brass Screws: These screws offer classic elegance. They suit furniture and cabinetry. They resist corrosion and add a warm, timeless charm.

Stainless Steel Screws: These provide a sleek, modern look. They complement contemporary designs. They resist rust and corrosion, ideal for moist areas.

Black Oxide Screws: These create a mysterious elegance. Their blackened surface offers a unique contrast, especially with light-colored materials.

Decorative Wood Screws: These blend seamlessly with wooden surfaces. They enhance natural beauty. They come in various head styles and finishes to match project themes.

Colored Screws: These inject personality and vibrancy. They allow for customization. They add an unexpected pop of color to projects like children’s furniture or crafts.

Light-Duty Connections

Wood screws excel in light-duty wood-to-wood connections. For small trim or brackets, #6 or #8 wood screws are appropriate. They typically measure 1 to 1½ inches long.

General Purpose Screws: These build shelves and repair cabinetry. They also fasten other non-structural light-duty projects.

Particle Board Screws: These construct and assemble cabinets and desks. They also work for other furniture pieces made of particle board.

Pocket Hole Screws: These apply to pocket hole joinery in cabinets and furniture. They also work for other woodworking projects.

Hardware Attachment

People commonly use wood screws to attach hardware components. These include hinges, brackets, locks, and handles. The screws provide a secure hold for these items.

Wooden Item Repair

Wood screws are effective for repairing wooden items. They fix areas where existing screws have stripped. This often happens in places with frequent movement or heavy loads. Hinges on doors, for example, experience significant wear. Overtightening during installation can also strip wood. This occurs when threads tear out wood fibers. Sudden stress or impact can also cause joints to fail. Wood screws help re-secure these damaged connections.

Misapplication Risks

Using the wrong type of screw can lead to serious problems. These issues range from minor cosmetic flaws to dangerous structural failures. Understanding these risks helps ensure project safety and longevity. Choosing the correct fastener prevents costly repairs and potential hazards.

Structural Failure

Incorrect screws in structural applications pose significant dangers. Construction screws are designed for heavy loads. Using standard wood screws in these critical areas can cause a structure to collapse. For example, a deck built with common wood screws instead of proper deck or structural exterior screws might fail under weight. These failures can result in injuries or property damage. Building codes specify fastener types for structural integrity. Ignoring these guidelines compromises safety.

Material Damage

The wrong screw can damage the material it fastens. Aggressive construction screws can split delicate wood. This happens when the screw’s threads are too coarse for the wood’s density. Conversely, using a fine-threaded screw in soft wood might strip the hole. This prevents a secure connection. Improperly chosen exterior screws can also react with treated lumber. This causes discoloration or accelerated corrosion of the fastener itself. Pre-drilling helps prevent splitting, but the screw type remains crucial.

Reduced Holding Power

Different screws have different holding capabilities. A screw designed for light-duty tasks will not hold heavy components effectively. For instance, a small gauge wood screw cannot secure a heavy cabinet to a wall. The threads might strip, or the screw could pull out. This reduces the connection’s overall strength. The project becomes unstable. The fasteners lose their grip over time. This leads to loosening or complete detachment.

Corrosion Issues

Corrosion is a major risk, especially for outdoor projects. Standard steel screws rust quickly when exposed to moisture. This weakens the fastener. It also stains the surrounding wood. Using interior screws outdoors is a common mistake. Proper exterior screws have specialized coatings. These coatings resist rust and other environmental degradation. Without this protection, the screws will fail prematurely. This compromises the entire structure’s durability.

Aesthetic Compromises

The appearance of a project can suffer from misapplied screws. A large, visible construction screw might look out of place in fine furniture. Countersinking a screw too deeply can damage the wood surface. Using screws with mismatched finishes can create an unprofessional look. For example, shiny zinc-plated screws might clash with rustic wood. Choosing the right head type and finish ensures a clean, professional appearance. This attention to detail enhances the project’s overall quality.

Installation Best Practices

Proper screw installation ensures project success and safety. Following best practices prevents damage and creates lasting connections. These guidelines help users achieve optimal results.

Screw Selection

Choosing the correct screw is the first step. Project requirements dictate the type of screw. Consider the material, load, and environment. Structural applications need construction screws. Lighter tasks use wood screws. Match the screw’s length and diameter to the material thickness. This prevents penetration through the other side.

Pilot Hole Importance

Pilot holes are crucial for many installations. They prevent wood from splitting, especially in hardwoods or near edges. A pilot hole guides the screw, ensuring a straight drive. The hole diameter should match the screw’s shank, not the threads. This allows the threads to grip the wood firmly. Always drill pilot holes for larger screws.

Driving Techniques

Use the right technique when driving screws. Apply steady, firm pressure. This prevents the bit from camming out of the screw head. Drive screws at a consistent speed. Too fast can strip the head or damage the material. Too slow can make driving difficult. Stop when the screw head is flush with the surface. Avoid over-tightening.

Correct Drive Bit

Always use the correct drive bit for the screw head. A mismatched bit can strip the screw head. This makes removal or further driving impossible. Phillips, Torx, and square drives each require specific bits. Ensure the bit fits snugly into the screw’s recess. This provides maximum torque transfer.

Safety Precautions

Safety is paramount during installation. Always wear safety glasses. Flying debris can cause eye injuries. Keep hands clear of the driving area. Power tools can cause serious harm. Read tool manuals before use. Store screws and tools properly after use.

Construction screws and wood screws serve distinct purposes. Construction screws provide superior strength for structural applications. Wood screws are ideal for lighter, non-structural wood connections. Understanding these differences in strength, application, and material compatibility is crucial. Choosing the correct type of screws ensures project success, durability, and safety. Always assess project needs and consult product specifications for the most appropriate fastener.

FAQ

What is the main difference between construction screws and wood screws?

Construction screws handle heavy loads and structural connections. They feature thicker shanks and aggressive threads. Wood screws connect lighter wood pieces in non-structural applications. They have finer threads designed to grip wood fibers.

Can someone use wood screws for structural projects?

No, wood screws are not suitable for structural projects. They lack the strength and load-bearing capacity of construction screws. Using them in structural applications can lead to project failure and safety risks. Always choose construction screws for load-bearing tasks.

Why do construction screws have special coatings?

Construction screws often have special coatings to resist corrosion. These coatings, like galvanizing or epoxy, protect the screws from moisture and harsh environments. This is crucial for outdoor projects and ensures the fastener’s longevity and structural integrity.

What happens if someone uses the wrong screw type?

Using the wrong screw type can cause several problems. It can lead to structural failure, material damage, or reduced holding power. For example, a wood screw in a structural application might break. An aggressive construction screw could split delicate wood.