Choosing the right nail is critical for any woodworking project’s success. Using the wrong nails can cause structural failure. For example, overdriving nails splits the wood, and bending nails compromises their grip. This leads to issues like nail withdrawal or wood fiber tearing. Poor nail choices also lead to aesthetic problems or wasted effort. Different types of nails vary significantly in design, material, and purpose. How do you navigate this variety of nails to achieve optimal results?

Key Takeaways

Choose the right nail for your project. Different nails work best for different jobs.

Nails have three main parts: the head, the shank, and the point. Each part helps the nail work well.

Common nails are for everyday tasks. Specialty nails solve unique problems, like holding wood in wet places.

Nail materials like stainless steel or galvanized coatings stop rust. This makes nails last longer outside.

The ‘penny’ system tells you a nail’s size. A longer nail needs to go deep into the wood for a strong hold.

Nail Anatomy Basics

Understanding the basic parts of a fastener helps you choose the right one. Each part plays a key role in how the fastener performs. You will find three main components: the head, the shank, and the point.

The Nail Head

The nail head is the top part of the fastener. You hit this part with your hammer. It also provides the main holding power. The head presses against the wood surface. Different nails have different head shapes. A flat, wide head, common on many construction nails, offers maximum grip. It prevents the fastener from pulling through the wood. Finish nails have a small, conical head. This head allows you to sink it below the wood surface. This creates a smooth finish. Some specialty fasteners even have no head at all for invisible attachment. The head’s design directly impacts its visibility and holding strength.

The Nail Shank

The nail shank is the long, slender body of the fastener. This part penetrates the wood. The shank’s design is crucial for its holding power. Smooth shanks rely on friction to stay in place. They are common for general use. Other nails feature specialized shanks. Ring shank nails have a series of circular ridges. These ridges interlock with wood fibers. This creates a very strong hold, resisting pull-out. Screw shank nails have threads, much like a screw. They twist into the wood, providing superior withdrawal resistance. The shank’s diameter also affects strength. Thicker shanks offer more structural integrity.

The Nail Point

The nail point is the sharp tip of the fastener. It helps the fastener enter the wood. The point’s shape affects how easily it penetrates and whether it splits the wood. Most nails use a diamond point. This point tapers to a sharp tip, cutting through wood fibers. A blunt point pushes wood fibers aside rather than cutting them. This can reduce wood splitting, especially in dense or brittle woods. Chisel points are flat on two sides. They help guide the fastener in a specific direction. Selecting the correct point helps ensure a clean, secure attachment without damaging your material.

Exploring Types of Nails

You now understand the basic parts of a nail. Next, you will learn about the many types of nails available. Choosing the right fastener can seem overwhelming. Many different types of nails exist. You can group these nails into broad categories. This makes understanding their uses much easier.

Think of nails as tools designed for specific jobs. Some nails are for heavy-duty construction. Others are for delicate finishing work. You will find nails made from different materials. These materials help nails perform best in various environments. For example, some nails resist rust. Other nails offer extra grip.

Generally, you can divide nails into two main groups: common nails and specialty fasteners. Common nails are your everyday workhorses. You use them for many general tasks. They are versatile and widely available. These nails include those for framing and basic carpentry.

Specialty fasteners, however, solve unique problems. They have specific designs for particular applications. For instance, you might need a nail that holds extremely well in soft wood. Or you might need a nail that you can easily remove. These specialized nails offer features that common nails do not.

Understanding these broad categories helps you narrow down your choices. You will learn about each type in more detail. This knowledge will guide you to select the perfect nail for your project. You will see how each nail’s design matches its intended purpose. This section sets the stage for exploring the specific types of nails you will encounter in woodworking.

Common Nails for Woodworking

You will find many general-purpose nails for various framing, construction, and general carpentry tasks. These are the workhorses of many projects. You use them for everyday jobs. They offer reliable fastening.

Common Construction Nails

Common construction nails are robust fasteners. They provide heavy-duty fastening capabilities. You use them for framing and general construction. These nails are essential for structural projects. They secure plywood in structural applications. You also use them for sheathing and roof decking. Common nails are typically steel. They often have zinc or galvanized coatings. These coatings add durability and prevent rust. They offer good holding power. They are also cost-effective and versatile.

The diameter or gauge of a nail is important. Thicker nails generally offer greater holding power. The right nail size depends on the wood type. It also depends on the specific application. Always consult a professional or manufacturer’s guidelines. This ensures you choose the correct nail size.

The design of nail heads is specific. It meets the load-bearing needs of different jobs. For example, interior framing needs particular load handling. Large, exposed nail heads are common here. The shank is the long part of the nail. It holds materials together through friction. Smooth shanks are common in framing. They are easy to drive. Some shanks have rings or grooves. These increase holding power. You see this in roof or wall sheathing. Building codes often require this withdrawal resistance. Framing nails are designed for heavy-duty structural integrity. You use them in wood framing for buildings. This includes walls, roof trusses, subflooring, and decking. They provide superior holding power. This is essential for structural applications. They come in various lengths and gauges. This meets different load-bearing needs.

Sinker Nails

Sinker nails have a thin, slightly conical shape. They often have a vinyl coating. This coating helps them drive into wood easily. You use these nails in framing and general construction. They are similar to common construction nails. However, their design helps them sink below the wood surface. This creates a smoother finish. The vinyl coating reduces friction. This makes driving them faster and easier.

Box Nails

Box nails are thinner than common nails. You use them in lighter wood applications. They help prevent wood splitting. This is a common problem with thicker nails. Their thinner design makes them ideal for delicate or lightweight materials. They provide a refined finish. You use box nails for light framing. They are also good for wooden crates and sheathing. They are usually steel. Sometimes they are galvanized. Box nails are not for heavy-duty applications. They do not have the strength for substantial construction projects.

Finish Nails

Finishing nails have small heads. This makes them less visible. They are ideal for attaching smaller trim pieces to wood. You use them for baseboards, for example. You can easily conceal their heads. You can set them below the wood surface. Then you fill the hole with putty. This creates a smooth, clean look. Finishing nails come in various sizes. They typically range from 1-penny to 8-penny. The largest is 4 inches long. It is made of 12-gauge wire. A larger penny number means a larger nail. You can find finishing nails from 1 inch to 3 ½ inches long.

Trim Work Application | Nail Length (inches) | Penny Size | Gauge (if specified) |

|---|---|---|---|

General Trim | 2″ to 2.5″ | 6d to 8d | |

General Trim | 2-penny to 4-penny | ||

Heavier Trim (window casing, door jamb) | 4-penny or 5-penny | ||

Quarter Rounds | 1-penny or 2-penny | ||

Baseboards | 1.5″ to 2″ | 5d to 8d | Thicker gauge |

Crown Molding | 6-penny or 8-penny |

Brad Nails

Brad nails are very thin. They have small heads. This makes them the thinnest nails for delicate trim work. You use them for small wood details. They are perfect for attaching small moldings. You also use them for paneling. Brad nails are less noticeable than other nails. They are often 18-gauge. This makes them ideal for delicate work. You can also find 16-gauge brad nails. These are stronger. They work well for baseboards and door casings. Some 15-gauge brad nails are available. These are for heavier trim applications. A brad is essentially a small, thin pin. You can think of it as a tiny pin fastener. This small pin helps secure delicate pieces without splitting the wood.

Casing Nails

Casing nails are for trim and molding. They offer a slightly larger head than finish nails. However, you can still conceal them. You use them for door and window casings. Their heads are small enough to countersink. Then you can fill the hole. This creates a clean finish. Casing nails have smooth shanks. Their head diameters include .141″, .172″, and .188″.

Specialty Wood Fasteners

You will find many specialized fasteners designed for unique challenges. These fasteners offer specific features that common nails do not. They solve particular problems in woodworking.

Ring Shank Nails

Ring shank nails have annular rings. These rings interlock with wood fibers. This provides strong holding power. They are especially effective for softwoods. Ring-shank nails offer roughly twice the withdrawal capacity of smooth-shank fasteners. This is for fasteners of the same nominal diameter. You use these fasteners in decking and siding. Their design allows wood fibers to lock into each groove. This provides a tighter grip. It withstands powerful weather conditions. This includes strong winds and constant moisture exposure. This enhanced grip strength makes them effective for siding and deck applications. They are good in high-wind areas. They resist popping out of the wood. The International Code Council (ICC) calls them “deformed” fasteners. This is due to their unique, annular design. It is engineered for a stronger, locking effect. You often choose these for exterior deck construction. These deck fasteners are also excellent for securing siding panels.

Screw Shank Nails

Screw shank fasteners have threaded shanks. These provide superior withdrawal resistance. They are primarily used in hardwoods. Their design allows them to spin during insertion. This is similar to a screw. It creates a tight groove in the material. This process helps prevent the material from splitting. It significantly reduces the likelihood of the fastener backing out. This ensures a more secure hold. You use screw shank fasteners in hardwoods and dense materials. They provide secure fastening and reduce splitting. Specific applications include flooring, siding, decking, pallets, and truss rafters.

Cut Nails

Cut nails have a wedge shape. They have a long historical use.

Until the 18th century, people individually hand-forged fasteners. This was a slow, expensive, and inconsistent process. This led to sparing use andpreference for joinery.

Jeremiah Wilkinson invented the cut nail in 1775. Jacob Perkins mechanized it in 1794. This revolutionized fastener production. It allowed mass production of uniform, stronger, and more durable fasteners.

By the mid-19th century, cut nails became the standard for construction. This accelerated the shift from timber framing to nail-reliant balloon framing. This made homes faster and cheaper to build.

Cut nails are particularly useful in hardwood flooring and restoration. In 1795, American inventor Jacob Perkins developed the cut-nail process. This involved cutting fasteners from sheets of raw iron. This significantly increased production efficiency and lowered costs. The cut-nail process, invented in the late 18th century, marked a turning point in fastener manufacturing. It allowed uniform fasteners to be produced in large quantities from sheets of metal. Cut nails quickly gained popularity for their strength and holding power. People widely used them in construction, shipbuilding, and industrial applications throughout the 19th century.

You can still find wrought square fasteners for historical restoration projects. You can get them from blacksmiths or vintage hardware suppliers. Some living history museums, like Colonial Williamsburg, maintain their own blacksmith shops. They make historically accurate forged fasteners. Tremont Nail Company is the only remaining American company producing square-cut fasteners. They use vintage nail-cutting machines from the 1850s. Tremont Nail Company produces square-cut fasteners from hardened, high-carbon steel. They offer hot-dipped galvanized versions for outdoor applications. You use square fasteners as concrete flooring fasteners. They secure wood flooring to concrete. You can also use them in cabinetry. For example, in glass display cabinets, they add an ‘old world’ feel.

Masonry and Concrete Nails

Masonry fasteners have hardened steel construction. You use them for fastening wood to concrete or masonry. These fasteners are made from tempered hardened steel. They are heat-treated. They typically have a 10-gauge shank. The shank type is usually smooth. Some have a tapered shank for unmatched grip. They feature a flat head style. They have a bright finish. Their construction grade aligns with ASTM F1667. Masonry fasteners are made of hardened steel. This steel is heated to extreme temperatures and quickly cooled. This makes very hard steel. They have a bright color/finish. Their head style is square. They have a tapered shank. Masonry fasteners are made of hardened steel. This prevents bending and breaking when penetrating solid concrete. They have a flat head. Their shank design is thick. Types include round, square, and fluted. A fluted shank offers the greatest holding surface. This provides a firm grip and prevents loosening. Galvanized coatings are available for galvanized concrete fasteners.

Roofing Nails

Roofing fasteners have broad heads and short shanks. You use them for securing shingles and underlayment.

Roofing Material | Nail Length (inches) | Head Diameter (inches) |

|---|---|---|

Standard Roofing Nails | 1 – 2 | At least 3/8 |

Asphalt Shingles | 1¼ (for standard installations) | At least 3/8 |

Wood Shakes | 1¾ or longer | At least 3/8 |

Slate Roofing | 2 or longer | At least 3/8 |

The head diameter is typically a standard 3/8-inch for all roofing fasteners. Roofing fasteners are available in lengths from one to two inches. Fasteners should completely puncture the decking. The entire diamond tip should be past the wood. For typical architectural shingles and 3/8-inch sheathing, you need 1-inch fasteners. Thicker sheathing, due to building codes, requires 1¼-inch fasteners. Thicker shingles may need longer fasteners for full penetration of the OSB. Ridge and hip shingles require fasteners about a half an inch longer. This penetrates more shingle layers.

Duplex Nails

Duplex fasteners have a double head design. You use them for temporary construction. This design allows easy removal. They are common in concrete formwork, scaffolding assembly, temporary fencing, pallets, crates, packaging, and landscaping. You use them for securing temporary wood structures. Their reusability reduces waste and costs. Visible heads prevent over-driving. Over-driving can compromise structural integrity or cause injuries. Clean removal minimizes surface damage. This reduces the need for repairs after dismantling. Duplex fasteners are frequently used in temporary construction frameworks. This includes scaffolding, formwork, and bracing. You also use them in log home construction. They accommodate natural settling. Their design allows for rapid assembly and disassembly. This reduces labor time. The visible upper head enables easy removal. This happens without damaging materials. This is crucial for reusable materials and maintaining structural integrity. In log homes, they allow for adjustments as the structure settles. This prevents issues from wood movement. They enhance safety by preventing over-penetration in scaffolding. They ensure structural stability. They also minimize wood cracking compared to standard fasteners.

Annular Ring Nails

Annular ring fasteners are also known as ring shank nails. They offer twice the strength of smooth shank fasteners. Their design allows wood fibers to lock into each groove. This provides a tighter grip. It withstands powerful weather conditions. This includes strong winds and constant moisture exposure. This enhanced grip strength makes them effective for applications such as siding and decking. They are especially good in high-wind areas. They provide excellent resistance to popping out of the wood. The International Code Council (ICC) identifies them as a “deformed” type of fastener. This is due to their unique, annular design. It is specifically engineered for a stronger, locking effect. You use these deck fasteners for enhanced grip. They are also great for siding.

Drywall Nails

Drywall fasteners have a specific design. This design attaches drywall to wood studs. The ring shank design is a key feature. It distinguishes these fasteners from smooth-shank fasteners. The rings on the shank act as small barbs. They grip the drywall and framing material more firmly. When you drive the fastener, these rings displace surrounding fibers. This creates a mechanical interlock. It significantly increases the fastener’s holding power. It prevents easy pull-out. The ring shank fastener was developed to address issues of pull-out. Its design features a series of small, raised rings along the shank. These rings function as tiny barbs. They increase the fastener’s holding power. They create more friction between the fastener, the drywall, and the stud. This enhanced friction helps prevent the fastener from pulling out. This is true even when subjected to stress. Drywall fasteners incorporate ringed shanks. This secures them in place after being driven through drywall and into a stud. They typically feature a cupped and concave head. This head helps conceal the fastener. It contributes to a smooth surface after the drywall finishing process.

Ring Shank or Annular Ring Nails: These fasteners feature rings around the shank. These rings increase friction within the drywall and stud. This enhances holding power and prevents loosening over time.

Cement Coated Nails: A cement coating on these fasteners improves grip. It helps the fastener remain in place despite material expansion and contraction.

Barbed Shank Nails: Similar to ring shank fasteners, barbed shanks further improve holding power. This makes them suitable for applications requiring maximum strength.

Flat Head: This head type offers a large surface area. It prevents the fastener from pulling through the drywall. You can easily conceal it with joint compound.

Countersunk Head: This head type is designed to sit flush or slightly below the drywall surface. It facilitates easier concealment with joint compound.

Nail Materials and Finishes

The material and finish of your nails significantly impact their performance. You need to choose the right material for durability and longevity. Different environments require different types of protection.

Steel Nails

Steel nails are the most common type. You use them for general construction. They offer good strength and are cost-effective. Their strength varies based on their diameter. For example, a 20d common nail with a 0.192-inch shank diameter has a minimum average bending yield strength of 80 ksi. Smaller diameter nails, like those less than or equal to 0.142 inches, can have a bending yield strength of 100 ksi.

Shank Diameter (inches) | Minimum Average Bending Yield Strength (ksi) |

|---|---|

0.192 (20d common nail) | 80 |

> 0.142 but <= 0.177 | 90 |

<= 0.142 | 100 |

Stainless Steel Nails

Stainless steel nails provide excellent corrosion resistance. You should use them in outdoor or damp environments. Type 316 stainless steel nails are highly recommended for severe-exposure environments. This includes coastal construction, marine hardware, and areas exposed to de-icing salts. Their superior corrosion resistance, especially against chlorides like salt and pitting corrosion, makes them ideal for long-term durability in harsh marine settings. This enhanced resistance comes from adding 2-3% molybdenum to their alloy. This significantly outperforms 304 stainless steel in such conditions. For saltwater exposures and any seaside application, always use Type 316 stainless steel siding nails. This grade contains molybdenum. It provides superior corrosion resistance in saltwater and other highly corrosive environments. This makes it the ultimate choice for such applications.

Galvanized Nails

Galvanized nails have a zinc coating. This coating protects the steel from rust. Hot-dipped galvanized (HDG) nails offer superior protection. A hot-dipped galvanized nail with a 50 μm zinc layer can last 89.3 years in local outdoor conditions. The zinc layer wears off at a rate of 0.6 μm per year. Hot-dip galvanized nails can last from 20 to over 50 years in outdoor conditions. The thickness of the zinc coating and environmental exposure influence this durability. In rural areas, the lifespan can exceed 50 years. In industrial or marine environments, it typically ranges from 20 to 30 years.

Coated Nails

Coated nails have special coatings. These coatings improve grip or provide specific colors. Vinyl-coated nails, for instance, drive more easily into wood. Other coatings might offer extra rust protection or blend with the material.

Copper and Brass Nails

Copper and brass nails offer both functional and aesthetic benefits. You use them for decorative purposes or in specific applications.

Copper Nails:

Functional: They resist corrosion. They provide a strong, long-lasting hold, especially for outdoor projects.

Aesthetic: Their distinct color adds a decorative touch to outdoor projects.

Brass Nails:

Functional: They are ideal for finer joinery work due to their small, subtle head. They also offer corrosion resistance.

Aesthetic: They add elegance. They provide a sophisticated look for high-end furniture or cabinet doors. They are valued for their distinctive gold-like appearance. You commonly use them in decorative nails and furniture tacks where aesthetics are important.

Nail Sizing Explained

Choosing the right size for your nails is just as important as picking the right type. Nail sizing affects how strong your connection is and how your project looks. You need to understand the different ways nails are measured. This helps you make the best choice for your woodworking tasks.

The Penny System

You will often see nails described using a “penny” system, like 6d or 10d. This system has a long history. It started in medieval England. Back then, people sold nails by the hundred. Their price was in pence. For example, you might buy “8d per 100 nails.” This practice led to classifying nail sizes by their price per hundred. This system was common by the fifteenth century. Over time, nails became standardized by size, not just price. For instance, in 1471, “fippenynayl” cost 4d per 100. This shows the early link between price and nail size. Today, the penny system still tells you the length and diameter of common nails.

Nail Length

Nail length is a straightforward measurement. You measure it from the underside of the head to the tip of the point. The length of your nails is crucial. It must be long enough to go through the first piece of wood and into the second piece. A good rule is to have the nail penetrate the second piece of wood by at least two-thirds of its thickness. This ensures a strong hold. Too short, and your connection will be weak. Too long, and the nail might poke through the other side.

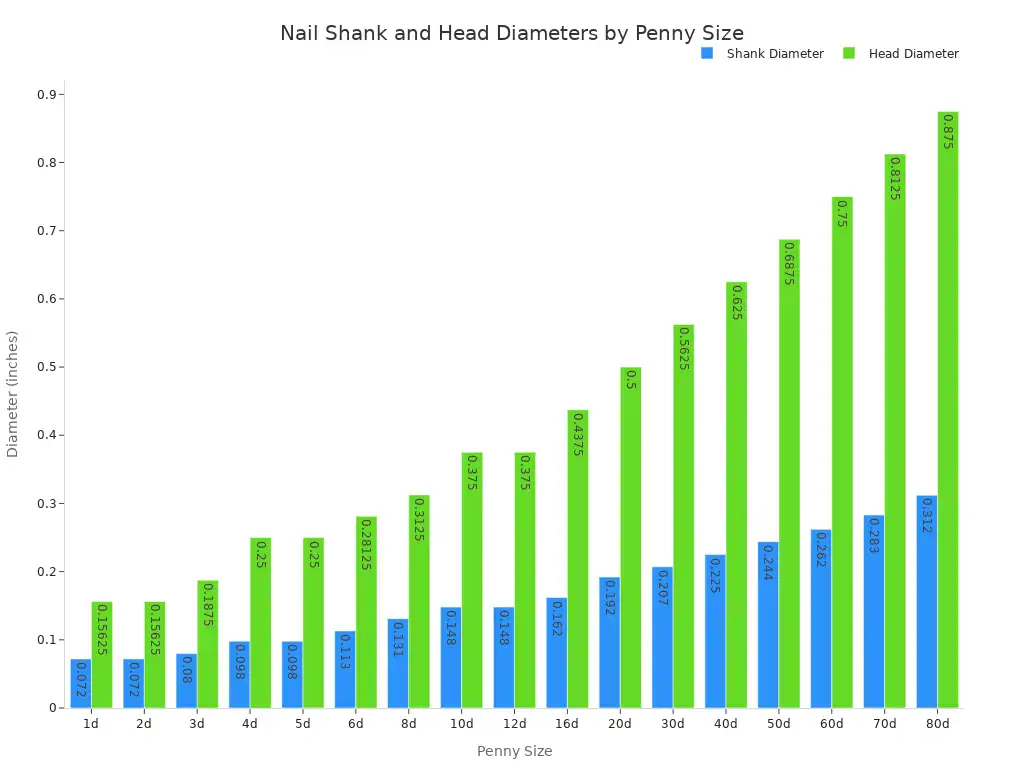

Nail Diameter

Nail diameter refers to the thickness of the nail’s shank. It also includes the size of its head. A thicker shank means a stronger nail. It provides more holding power. However, a very thick nail can split thinner wood. You need to balance strength with preventing damage. The head diameter also matters. A larger head offers more surface area to hold materials together.

Here is a look at typical diameters for common nails:

Penny Size | Shank Diameter (in) | Head Diameter (in) |

|---|---|---|

1d | 0.072 | 5/32″ |

2d | 0.072 | 5/32″ |

3d | 0.080 | 3/16″ |

4d | 0.098 | 1/4″ |

5d | 0.098 | 1/4″ |

6d | 0.113 | 9/32″ |

8d | 0.131 | 5/16″ |

10d | 0.148 | 3/8″ |

12d | 0.148 | 3/8″ |

16d | 0.162 | 7/16″ |

20d | 0.192 | 1/2″ |

30d | 0.207 | 9/16″ |

40d | 0.225 | 5/8″ |

50d | 0.244 | 11/16″ |

60d | 0.262 | 3/4″ |

70d | 0.283 | 13/16″ |

80d | 0.312 | 7/8″ |

Nails for Power Tools

When you use power tools for woodworking, you often need special nails. These nails come in strips or coils. This makes loading your nail gun fast. You can drive many nails quickly. This saves you time and effort on big projects.

Collated Nails

Collated nails are joined together. They come in different forms. Each form works with specific nail guns.

Wire Weld: These nails have rounded heads. Thin wire strips hold them together. You use them for 15-degree coil nailers. They are popular for roofing, siding, fencing, and framing.

Plastic Strip: Plastic strips hold these nails. They have fully-rounded heads. You find them in 21-degree nailers. They work well for framing and siding.

Paper Tape: Paper strips hold these nails. They often have clipped or offset heads. You use them in 30-degree nailers. They offer a larger capacity. They also fit into tight corners.

Coil Nails (Wire Weld): These nails are wound in a coil. Air-operated coil nailers use them. Wire holds the nails together. They are efficient and reduce jams.

Nail Gun Compatibility

Your nail gun needs specific collated nails. You must match the nails to your tool. Several factors determine compatibility.

Method of Collation: Nails can use plastic strips, paper strips, thin wire, or adhesive tape. Plastic strips are durable and water-resistant. Paper strips offer higher load capacity. Adhesive is for finish nails.

Degree or Angle of Collation: This angle ranges from 0° to 35°. Your nail gun is designed for a specific angle.

Head Type: Nails can have full round or clipped heads. Clipped heads allow more nails per strip. However, building codes might restrict them in some areas.

Length and Gauge Limitations: Your nailer has limits on nail length and thickness. You must check these limits. This ensures your nails fit and work correctly.

The best nail for your project depends on many factors. You must consider the wood type and environmental conditions. Think about structural needs and aesthetic goals. Understanding different types of nails, materials, and sizes empowers you. You make confident choices about these important nails. These choices ensure durability, safety, and a professional finish for your work with wood. Apply this knowledge about nails to your future projects. Proper selection of nails is a cornerstone of quality craftsmanship. You will choose the right nails every time.

FAQ

What nail should I use for outdoor projects?

You need nails that resist rust. Choose stainless steel nails, especially Type 316 for saltwater areas. Galvanized nails also offer good protection against corrosion. These choices ensure your outdoor projects last a long time.

Can I use common nails for trim work?

No, common nails have large heads. They are too visible for trim. You should use finish nails or brad nails instead. These nails have small heads. You can easily hide them for a clean look.

What does the “penny” system mean for nails?

The “penny” system (like 6d or 10d) tells you a nail’s length and diameter. A higher penny number means a longer and thicker nail. This system helps you choose the right size for your project.

How do I prevent wood from splitting when nailing?

Use thinner nails like box nails for delicate wood. You can also blunt the nail’s tip slightly with a hammer. This pushes wood fibers aside instead of cutting them. Pre-drilling a small pilot hole also helps prevent splitting.