Do you struggle with limited space, disorganization, or an uncomfortable setup for your sewing projects? A custom sewing machine cabinet provides the ultimate solution. This DIY sewing table offers a tailored fit, integrated storage, and improved posture. You save money compared to store-bought options. Many free DIY Sewing Machine Cabinet Plans are available online. This guide will help you explore various plans and considerations for building your own perfect sewing space.

Key Takeaways

Building your own sewing cabinet saves money. It gives you a custom fit for your machine. You also get storage that fits your needs.

Plan your project carefully. Measure your space and sewing machine. Think about what you need to store. Choose materials like plywood or MDF.

Many types of plans exist. You can build a simple table or a cabinet with lots of storage. Some plans let you adjust the table height.

Use the right tools for building. Always measure twice before you cut. Test fit parts before you glue them. This helps avoid mistakes.

Add personal touches to your cabinet. You can add power strips for cords. Good lighting helps you see your work better.

Benefits of a DIY Sewing Cabinet

Custom Fit and Function

Building your own diy sewing cabinet offers unmatched customization. You can design a cabinet that perfectly fits your specific sewing machine. This means no awkward gaps or wasted space. You also tailor the dimensions to your available room. This ensures your workspace integrates seamlessly into your home. You get a functional piece that meets your exact needs.

Enhanced Organization

A custom diy project allows for integrated storage solutions. You can include drawers, shelves, and cubbies designed for your sewing notions. Imagine dedicated spots for thread, bobbins, and fabric scraps. This keeps your workspace tidy and efficient. You will spend less time searching for supplies and more time creating.

Ergonomic Workspace

An ergonomic sewing table is crucial for comfort. You can set the ideal working height for your body. This prevents strain on your back, neck, and shoulders. Research shows that adjustable table heights can reduce back discomfort immediately. You can choose to sit or stand while you sew. This flexibility helps prevent shoulder, spinal, back, or wrist pain. An adjustable table allows for longer sewing sessions without discomfort. You can even lower the table for children, making learning safer.

Budget-Friendly Options

Choosing to build your own sewing table saves you money. Store-bought options can be expensive. You can often complete a diy project for materials costing around $121-$150. This is a significant saving. Beyond the cost, you gain a rewarding sense of accomplishment. You create a functional and beautiful piece with your own hands.

Planning Your DIY Sewing Table

Before you start your diy sewing table project, careful planning is essential. This ensures your new workspace meets all your needs. You will make smart choices about space, storage, design, and materials.

Space and Machine Fit

First, measure your available area. This helps you decide the size and style of your diy sewing table. Consider where you will place the table. Will it be a permanent fixture or something you can fold away?

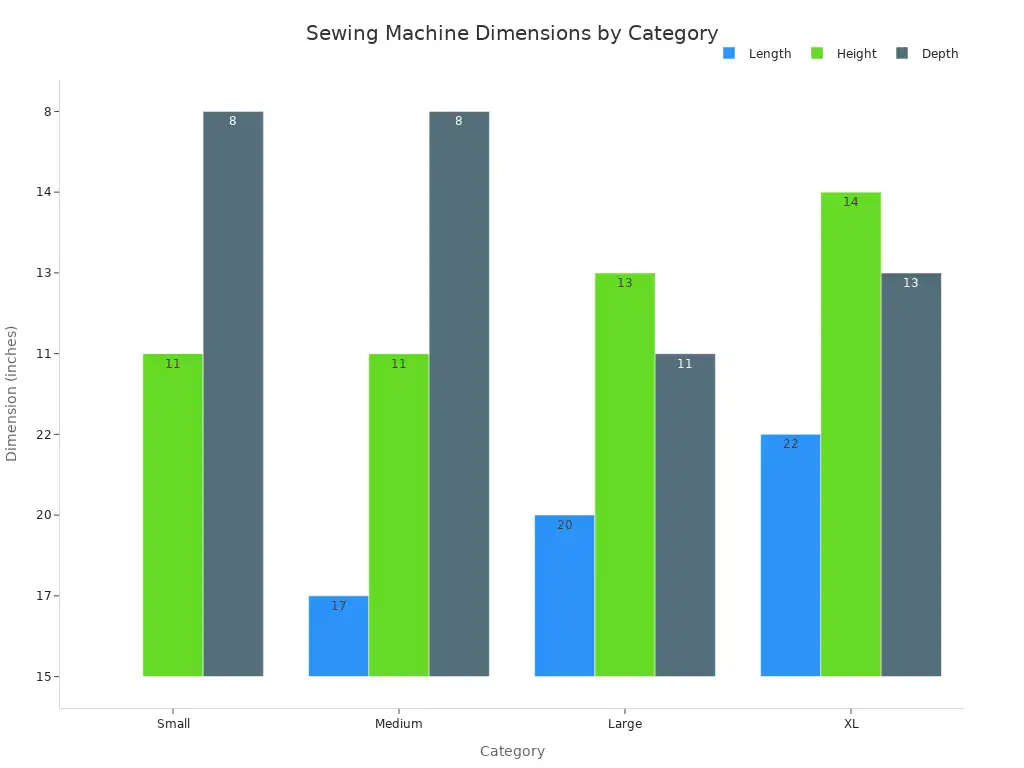

Next, measure your sewing machine. You need to ensure proper fit and clearance. Different machines have different sizes. Here are common dimensions for popular sewing machine models:

Category | Length | Height | Depth |

|---|---|---|---|

Small | 15″ | 11″ | 8″ |

Medium | 17″ | 11″ | 8″ |

Large | 20″ | 13″ | 11″ |

XL | 22″ | 14″ | 13″ |

Make sure your chosen plans accommodate your machine’s exact measurements.

Storage Requirements

Think about what you need to store. List all your essential sewing items. This includes thread, fabric, scissors, and other tools. Do you need many drawers or open shelves? Planning your storage now helps you choose the right diy sewing table design.

Design and Materials

You can choose from different cabinet styles. Options include freestanding, fold-out, or built-in designs. Each style offers unique benefits. For materials, plywood and MDF are common choices.

Material | Pros | Cons |

|---|---|---|

Plywood | – Stronger than MDF, offering excellent resistance to warping and cracking. | – Edges may require finishing over time to prevent moisture damage. |

MDF | – Smooth surface, ideal for painted finishes. | – Less durable and strong than plywood. |

Plywood is stronger and resists warping. MDF is smoother and more affordable for painted finishes. Consider hardware like hinges and drawer slides too.

Matching Your Skill

Choose plans that match your DIY experience. Some build projects are simple. Others require advanced woodworking skills. Start with a simpler design if you are new to building. You can always tackle more complex sewing projects later.

Diverse DIY Cabinet Plans

You can find many different types of diy sewing machine cabinet plans. These plans help you create the perfect workspace. They range from simple table designs to complex storage solutions.

Table-Focused Designs

Some diy sewing table plans focus on providing a great work surface.

Simple Drop-Leaf Table Cabinet: This design is perfect for small spaces. You can easily build it. It gives you an extended work surface when you need it. Then, you can fold it down to save room. For example, the “DIY Sewing Cabinet from Cottage Hill” transforms an armoire into a complete sewing station. It has a fold-down table for sewing and cutting. You can close it up and hide the station when you are not using it. Another option is the “Super Easy Sewing Desk from A Beautiful Mess.” This small table fits tight spaces. It is great for beginner builders. It can also work as a simple desk. The “DIY Sewing Table from Pearls & Scissors” is another easy-to-build option. You can construct it in an afternoon. It uses pre-built trestles and fits well in a corner.

Sturdy Fixed-Table Cabinet: This design is robust. It often includes integrated shelves or cubbies right below your sewing machine. You get a solid, permanent workspace.

Adjustable Height Sewing Table: This type focuses on ergonomics. You can find plans for manual or electric height adjustment. These tables often have sturdy construction, using high-grade steel. This ensures durability and stability. They offer a spacious work surface. Some even have a detachable side table. You get ample space for fabrics and tools. These tables feature powerful motors for smooth height transitions. You can move from sitting to standing positions easily. They also have an adjustable sewing platform. This accommodates various sewing machines. An advanced control panel lets you save custom heights. You can also find models with easy-roll locking casters for movement.

Modifying Existing Furniture: You can upcycle an old piece of furniture. For instance, you can take a table from a marketplace and add a recessed machine. People have successfully transformed bar carts, coffee carts, and even old treadle table bases. You can turn them into drink stations, make-up stations, or writing desks. Some even become kids’ craft stations or outdoor flower planters.

Storage-Rich Designs

These plans prioritize organization. They help you keep all your sewing supplies tidy.

Cabinet with Multiple Drawers and Thread Organizers: This design maximizes small item storage. It includes dedicated thread racks. You can keep all your notions in their place.

Fold-Out Cabinet with Hidden Compartments: This cabinet is compact when closed. When you open it, it reveals extensive storage and a large work surface. Rockler.com offers a ‘Compact Sewing Machine Cabinet Downloadable Plan/Instructions’. This plan provides step-by-step instructions. It includes full-color photographs and illustrations. This sewing center folds out to create a spacious work surface. Then, it neatly closes into a compact cabinet.

Modular Storage Units: You can build separate units. For example, you can build a drawer base and a shelf unit. Then, you combine them to fit your needs.

Large 4×5 Foot Table with Drawers and Shelving: This design provides a huge workspace. It includes two drawers on each side and shelving inside. You get plenty of room for fabric and tools.

Specialized Cabinet Features

You can add specific features to enhance your sewing experience.

Flush-Mount Options: You can build a box to flush-mount your sewing machine into a table. This creates a perfectly even surface. This setup offers practical and aesthetic benefits. It provides organized storage and an ergonomic work environment. This design minimizes strain on your back and shoulders. It offers an ideal height for your sewing machine. You get ample workspace. This allows you to focus on your craft without discomfort. Properly leveling your sewing machine with the surrounding surface is crucial. This ensures smooth fabric feeding and even stitching. You will feel less tired at the end of your sewing day. You can also expect more consistent seams. A recessed machine provides more ease with Free Motion Quilting. It prevents the quilt from getting hung up.

Sources for Plans: You can find many free diy sewing table plans online. They often come with detailed instructions and PDF guides. Websites like Rockler and Etsy also offer unique designs.

Tools, Materials, and Building Your Cabinet

Building your own diy sewing table requires the right tools and materials. You also need a clear understanding of the construction process. This section details what you need and how to approach your build.

Essential Tools and Supplies

You need a mix of power tools and hand tools for this project.

Power Tools: A circular saw helps you make long, straight cuts. A miter saw creates precise angle cuts. A jigsaw cuts curves or intricate shapes. A drill makes pilot holes and drives screws. A pocket-hole jig is useful for strong, hidden joints.

Hand Tools: You need a measuring tape for accuracy. A square ensures your cuts are straight. Clamps hold pieces together while glue dries. Sandpaper smooths rough edges.

Safety Gear: Always prioritize safety. Wear safety glasses or goggles to protect your eyes from debris. Use hearing protection, especially with loud tools. A dust mask or respirator protects your lungs from wood particles. Wear sturdy work gloves and closed-toe shoes for extra protection.

Fasteners & Adhesives: You will need wood screws for strong connections. Wood glue adds extra strength to joints. Hinges are necessary for fold-out sections or doors. Drawer slides ensure smooth operation for your drawers.

Finishing Supplies: Choose paint, stain, or polyurethane to protect and beautify your finished project.

Core Construction Phases

Building your sewing table involves several key steps.

Cutting Materials: Accurate measurements are crucial. You must ensure square cuts. Use a sliding table set at 90 degrees to cut the first end of each part. Then, crosscut multiple parts to the same length using the rip fence. For sheet goods, rip the first edge slightly over-width. Then, turn the piece around and rip the other edge to the exact size. This gives you two square, clean edges for joinery. After ripping, cut parts to length, making sure the ends are square. You can use a track saw or a miter saw for this. Mark each part with an identifying label, like ‘upper 1, left side,’ as you cut it.

You can choose different cutting techniques for strong joints. Rabbet cuts create a step or recess along the wood’s edge for seamless connections. Dado cuts make a wide groove across the wood for shelves or panels. Dovetail joints offer strength and beauty with interlocking wedge shapes. Mortise and tenon joints involve a cavity in one piece and a projecting part from another. These are simple yet strong. Choose techniques based on your wood type and project size.

Assembling the Frame: Secure joints and ensure sturdy construction. Use wood glue and screws for strong connections. Clamps hold pieces together while the glue dries.

Installing Drawers/Shelves: Smooth operation and proper alignment are key. First, identify the type of drawer slide you will use. Side-mount slides are easiest for beginners. Undermount slides offer quiet operation and a clean look. Measure the drawer length and the cabinet depth. Measure the drawer’s width and the cabinet opening. This helps you determine the required thickness for side-mount slides. Leave enough space for slide clearance. This prevents scraping. Measure all components at least twice to avoid mistakes.

To install, remove any old hardware. Mount brackets in the cabinet. Attach the slides to the cabinet, ensuring they are level and square. Prepare the drawer box by locating pre-cut notches and securing retention clips. When inserting the drawer box, ensure it is clean. Apply a small amount of lubricant to the glide tracks. Align the drawer box carefully with the installed glides. Slowly slide the drawer in. If you feel resistance, pull it out, check alignment, and try again. Test the operation by sliding the drawer in and out. Make small adjustments if it does not move smoothly. Tighten all screws securely.

Creating the Machine Platform: You can choose recessed or flush mount options. Some plans use a lift mechanism. To create a recessed platform, install a pair of plywood lift supports inside the cabinet. Glue and screw the top support in place. Then, secure the second support with glue and screws. Make sure the covered edge faces the top of the cabinet. Attach the sewing machine lift hardware to these supports. Rout out the sewing machine platform from the top work surface. You can use an MDF cutting guide (11-1/8″ x 19-3/8″ rectangle) to guide your router. Perform this in several deepening passes. Sand the edges of the sewing machine platform and its opening smooth. Mount the sewing machine platform to the lift mechanism.

Finishing Your Project

After assembly, focus on the finishing touches. Sand all surfaces smooth. This prepares the wood for paint or stain. Apply your chosen finish. This protects the wood and enhances its appearance. Finally, install all hardware, such as handles for drawers or pulls for doors. Your custom diy sewing table is now ready for use.

Tips for a Successful Cabinet Build

You want your custom sewing space to be perfect. Follow these tips for a smooth and successful diy project. These steps help you avoid common problems.

Accuracy and Testing

Precision is key when you build your cabinet. Always measure twice before you cut. This simple rule prevents costly mistakes. After cutting, test fit all your components. Do this before you use glue or permanent fasteners. This ensures everything aligns correctly.

Avoid common mistakes during assembly.

Read the Instructions: Do not skip the manual. Read it thoroughly. Check for all parts. Highlight any confusing steps.

Use the Right Tools: Always use the tools and fasteners the plan specifies. Substituting them can damage materials. It can also weaken the frame.

Do Not Over-Tighten Screws: Tighten screws until they are snug. Do not strain them. Over-tightening can crack panels. It can also weaken pre-drilled holes.

Assemble in the Right Space: Build your cabinet in its final room. This ensures it fits through doorways. It also protects your floors.

Customization and Details

Make your cabinet truly yours. Personalize the finish to match your home decor. You can paint it a bright color. You can stain it to show the wood grain. This makes your sewing table unique.

Enhancing Functionality

Add features to make your workspace even better.

Power Strips: Place power strips in under-cabinet areas. This keeps cords out of sight. It also prevents tripping hazards. You can use power strips with mounting capabilities. Secure them to your cabinet. This improves organization.

Task Lighting: Good lighting is important for sewing. Integrate under-cabinet lighting with power strips. This gives you both light and power access. Design a lighting plan for even light distribution. This prevents dark spots. You can add dimmers to adjust brightness. Choose LED lights for energy efficiency. Ensure proper placement to avoid shadows.

You can build a personalized, organized, and ergonomic sewing haven. Embark on your own building journey. Careful planning and resources, including numerous free diy sewing machine cabinet plans, make it achievable. This blog provided a range of diy sewing table plans and essential guidance. You can create your dream sewing space. A custom diy sewing cabinet or diy sewing table transforms your sewing experience. Explore more diy sewing machine cabinet plans to find your perfect design.

FAQ

What materials work best for a DIY sewing cabinet?

You can use plywood or MDF. Plywood offers strength and resists warping. MDF has a smooth surface, great for painting. Both materials provide a good base for your custom cabinet. Choose based on your budget and desired finish.

What types of DIY sewing cabinet designs can you build?

You can build several designs. A drop-leaf table saves space. A fixed-table cabinet offers a sturdy workspace. Adjustable-height tables provide ergonomic benefits. You can also modify old furniture for a unique look.

What essential tools do you need for building a sewing cabinet?

You need basic power tools. These include a circular saw, miter saw, and drill. Hand tools like a measuring tape and clamps are also necessary. Always wear safety gear, such as goggles and gloves, to protect yourself.

What is a flush-mount sewing machine platform?

A flush-mount platform means your sewing machine sits level with the tabletop. This creates a smooth, even work surface. It helps fabric feed easily. This design also reduces strain on your body while you sew.