You might wonder how many coats KILZ metal primer you need for effective protection. Generally, one to two coats work best. The exact number, however, depends on several specific factors. Proper priming for metal surfaces is very important. It prevents rust and ensures your paint lasts a long time. This sets the stage for understanding how many coats KILZ metal primer is truly necessary for your project.

Key Takeaways

Use one to two coats of KILZ metal primer for most projects. The exact number depends on your specific needs.

KILZ metal primer helps paint stick better and stops rust. It makes your final paint job look smooth and last longer.

Check the metal’s condition, type, and your final paint color. These factors help you decide how many primer coats to use.

Prepare the metal surface well before priming. Clean it, remove rust, and let it dry completely for the best results.

Avoid using too much primer. Too many coats can cause cracking or peeling. Follow product instructions for the best finish.

KILZ Metal Primer’s Purpose

Primer’s Role in Adhesion and Protection

KILZ metal primer plays a crucial role in your painting projects. It does more than just add another layer. You use it to enhance topcoat adhesion. This means your final paint coat sticks much better to the metal surface. Without primer, paint often struggles to bond. For example, paint can scratch off easily from unprimed metal. You might see paint chipping on a metal barrel if you do not prime it first. Thin layers of paint do not bond well to sanded metal pieces without primer. This primer also provides corrosion resistance. It creates a protective barrier. This barrier shields the metal from elements that cause rust. Finally, primer creates a uniform surface. This helps your topcoat look smooth and even.

Why Metal Surfaces Need Priming

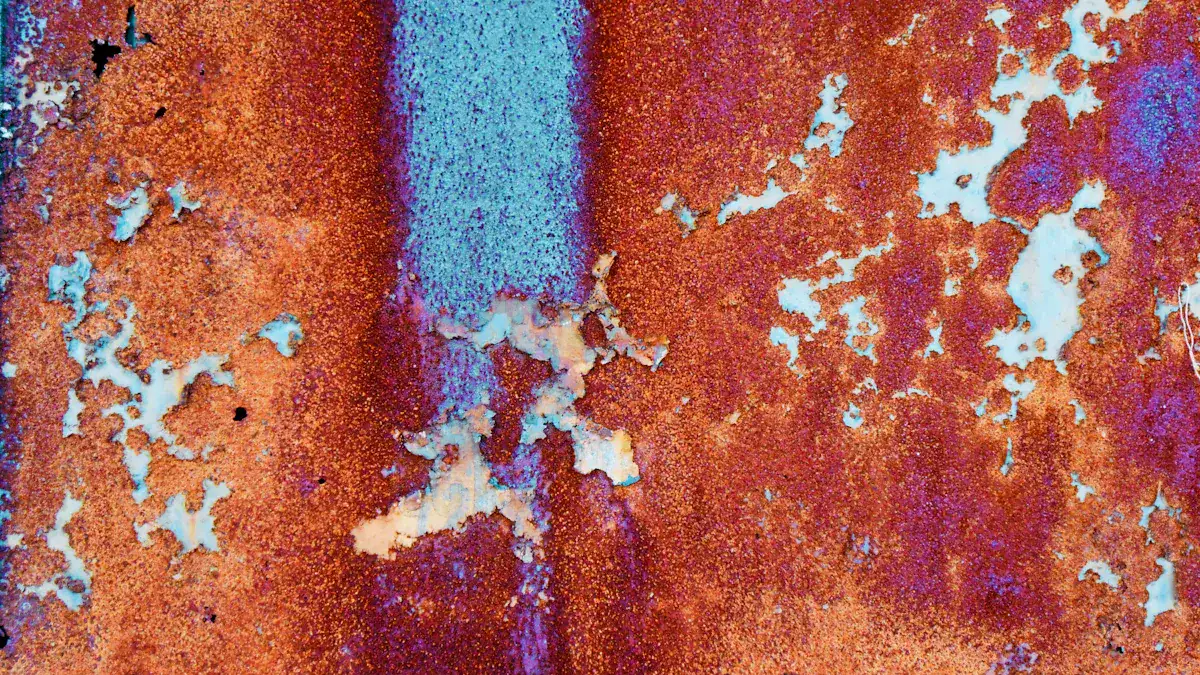

Metal surfaces need priming because they are vulnerable to damage. They can corrode easily. Corrosion weakens the metal and ruins its appearance. Many types of corrosion affect unprimed metal surfaces.

Uniform Corrosion: This type attacks the entire surface. It makes the metal lose thickness over time. You often see it as reddish-brown rust on steel.

Galvanic Corrosion: This happens when two different metals touch. One metal corrodes faster than the other.

Pitting Corrosion: This creates small holes or pits on the metal surface.

Crevice Corrosion: This occurs in tight spaces where moisture gets trapped.

Erosion Corrosion: This combines wear from moving fluids with corrosion.

Microbiological Influenced Corrosion (MIC): Microscopic organisms cause or speed up this type of corrosion.

KILZ primers offer specific benefits. KILZ 2 ALL-PURPOSE Primer has enhanced hiding capabilities. This helps cover old colors or stains. KILZ 2 Water-Based Latex blocks medium stains. It also resists mildew. These features help you achieve a clean, protected, and uniform base. This base is essential for a long-lasting paint finish.

Factors for Primer Coats

Several factors influence how many coats of KILZ metal primer you need. You must consider these before you start your project.

Metal Surface Condition

The condition of your metal surface matters a lot. If the metal is new and clean, you might need fewer coats. A smooth, rust-free surface accepts primer well. If the metal has rust, you must prepare it thoroughly. You need to scrape, sand, or even sandblast it. An acidic solution can also help. After cleaning, you will likely need more primer coats. This ensures proper rust inhibition.

Type of Metal

The type of metal you are priming also affects your decision. Different metals have different challenges.

Ferrous metals (iron-based): These metals rust easily. You need an oil-based primer. You must watch for and remove rust.

Non-ferrous metals (e.g., galvanized metal, aluminum): These metals often do best with a water-based primer. New galvanized metal is especially tricky. It has factory oils and other contaminants. You must clean these off thoroughly. Do not leave any residue. Aluminum can also form an oxidation layer. This layer prevents paint adhesion. You need etching primers for these metals. This ensures proper adhesion. It also prevents future paint failure.

Galvanic corrosion is another concern. This happens when two different metals touch. An electrolyte, like water, must be present. Steel and aluminum are challenging metals. They are low on the anodic list. This means they corrode easily. Steel is often galvanized with zinc. Zinc corrodes sacrificially. It protects the steel. Many weld-through primers contain zinc for this reason.

Topcoat Requirements

Think about your final paint color. If you are painting a dark color over a light surface, one primer coat might be enough. If you are painting a light color over a dark or stained surface, you will need more primer. This helps achieve true color. It also ensures good coverage.

Application Method

How you apply the primer can change the number of coats. Spraying often gives a thinner, more even coat. You might need two thin spray coats for full coverage. Brushing or rolling can apply a thicker coat. You might achieve good coverage with just one coat. Always aim for even application.

Environmental Factors

The environment where you apply the primer is important.

Lower temperatures, high humidity, or poor ventilation affect dry time.

You should only apply primer if surface, air, and product temperatures are between 50°F and 90°F (10°C and 32°C).

Heavy application can also increase dry and recoat times.

KILZ ADHESION primer is a water-based, modified-acrylic primer. It bonds to tough-to-paint surfaces, including metals. You must follow the temperature guidelines. This ensures proper adhesion and curing.

How Many Coats KILZ Metal Primer: Guidelines

You often ask, “how many coats Kilz metal” primer do I need? The answer depends on your specific project. You want to achieve the best results. Understanding these guidelines helps you decide.

When One Coat is Enough

You can often use just one coat of KILZ metal primer. This works well in certain situations. For example, if you are priming new, clean metal, one coat usually provides enough protection. The surface is already smooth and free of rust. The primer adheres easily. You also need only one coat when the primer applies uniformly over the previous color. This is especially true if you use a primer with enhanced hiding capabilities, like KILZ 2 ALL-PURPOSE. This type of primer covers existing colors effectively. It creates a consistent base for your topcoat. You save time and material when one coat does the job.

When Two Coats are Best

You should apply two coats of KILZ metal primer in several key situations. This provides superior protection and a better finish.

Rusted Metal: If you are priming metal that had rust, two coats are essential. Even after you clean and prepare the rusted areas, a second coat adds an extra layer of corrosion resistance. It ensures the primer fully seals the surface.

Significant Color Changes: You need two coats when you paint a light color over a very dark surface. The first coat helps block the old color. The second coat ensures complete coverage and true color development for your topcoat. For challenging color changes, you might even apply two coats of light gray primer. Then, you follow with one coat of white KILZ primer. This creates a perfect, neutral base.

Porous or Uneven Surfaces: Some metal surfaces are more porous or have an uneven texture. A single coat might not fully penetrate or cover these areas. Two coats ensure complete adhesion and a smooth, uniform base.

High-Traffic Areas: For metal items that experience a lot of wear and tear, two coats offer increased durability. This extra layer protects against chips and scratches.

Applying two coats gives you peace of mind. You know your metal surface has the best possible foundation.

Avoiding Over-Priming

You might think more primer means better protection. However, over-priming can cause problems. Applying too many coats of KILZ metal primer can lead to issues. The primer might crack or peel later. This happens because thick layers do not cure properly. They remain soft underneath. You also waste material and time. Excess primer takes longer to dry. It can create an uneven surface. This makes your final paint job look less professional. You want to achieve the right balance. Follow the product instructions. Assess your specific project needs. This helps you determine “how many coats Kilz metal” primer you truly need. You aim for optimal adhesion and protection, not excessive layers.

Best Practices for Metal Priming

You want your metal priming project to succeed. Following best practices helps you get the best results.

Essential Surface Preparation

Proper surface preparation is key. You must prepare the metal surface before you apply any primer. First, you need to remove rust, loose or peeling paint, and any other foreign matter. Then, you clean the surface with an appropriate cleaner or degreaser. You must rinse it thoroughly. Finally, you allow the surface to dry completely. This ensures the primer sticks well.

Application Techniques

How you apply the primer matters. You should use smooth, even strokes. This prevents drips and runs. You can use a brush, roller, or sprayer. Each method has its own benefits. A sprayer gives a very smooth finish. A brush helps you get into small areas. Always apply thin, even coats. This helps the primer dry correctly.

Drying Times

Drying times are important. You must let the primer dry fully between coats. You also need to let it dry before you apply your topcoat. Check the KILZ product label for specific drying times. These times can change based on temperature and humidity. Cooler temperatures and high humidity make drying take longer.

Troubleshooting Primer Issues

Sometimes, problems happen. You might see blisters or peeling. Blistering means bubbles form in the coating. This can happen from moisture under the coating or if you apply coats too thick. To fix this, you remove the blisters. You sand the area smooth. Then, you clean and dry the surface well. Peeling, or delamination, means the primer lifts off. This often happens from poor surface preparation. You might not have cleaned the surface enough. To fix peeling, you remove all loose coating. You sand the surface to make it rough. Then, you prime it again.

If you see brush strokes or roller patterns, you can fix them. You sand the surface smooth. Then, you reapply the primer. You use the right brush or roller for the job. You also keep a wet edge as you paint. This helps create a seamless finish.

You now understand how many coats KILZ metal primer you need. For most applications, one to two coats are the primary recommendation. This answers “how many coats Kilz metal” primer is generally needed. Your decision on how many coats KILZ metal primer to apply depends on key factors. Consider the surface condition, metal type, and your desired finish. Always follow product instructions. You must assess your project’s specific needs for optimal results. Proper KILZ metal primer application gives you robust protection and a durable finish.

FAQ

What is the main purpose of KILZ metal primer?

KILZ metal primer enhances paint adhesion. It also provides corrosion resistance. You use it to create a uniform surface for your topcoat. This helps your paint last longer.

How long should I wait before applying a second coat of primer?

You should wait at least one hour before applying a second coat. Always check the specific KILZ product label. Drying times can vary. Temperature and humidity affect drying.

Can I use KILZ metal primer on rusty surfaces?

You can use KILZ metal primer on rusty surfaces. First, you must remove all loose rust. Clean the area thoroughly. The primer then seals the surface. This helps prevent further corrosion.

What types of paint are compatible with KILZ metal primer?

You can use most latex and oil-based paints over KILZ metal primer. It creates a versatile base. Always check the compatibility of your chosen topcoat. Read both product labels carefully.

Is surface preparation really necessary before priming metal?

Absolutely, surface preparation is essential. You must clean, degrease, and often sand the metal. This ensures the primer adheres properly. Good preparation prevents future paint failure.

💡 Tip: Proper preparation is key for a durable finish!