Accurate measurement plays a fundamental role across various fields, from DIY projects to professional engineering. Inaccurate measurements affect 55% of DIY enthusiasts, often leading to project failures. Measuring tools are instruments for determining dimensions, ensuring precision in tasks. This post examines three essential measuring tools: the ruler, measuring tapes, and calipers. These common types of measuring tools help achieve exact measurement. Understanding each measuring tool’s unique capabilities is crucial for successful outcomes. Many different types of measuring tools exist, but this article focuses on these three fundamental types, which offer great precision.

Key Takeaways

Rulers are basic tools for measuring short, flat lengths and drawing straight lines. They come in different materials like plastic or wood for various tasks.

Measuring tapes are flexible tools for measuring long distances or curved objects. They are useful in construction, sewing, and home projects.

Calipers are precision tools that measure small, exact distances. They are important for engineering, machining, and jewelry making where accuracy is key.

Choosing the right measuring tool depends on your project’s needs. Consider how accurate you need to be, the material you are measuring, and the work environment.

Each tool has unique strengths. Rulers are for simple tasks, tapes for longer or curved measurements, and calipers for very precise work.

Rulers: Essential Measuring Tools

What is a Ruler

A ruler is a basic linear measuring tool. It helps determine length or distance. People also use a ruler to draw straight lines. This simple measuring tool is fundamental in many fields. It provides a straight edge for various tasks.

Common Ruler Types

Many types of rulers exist for different purposes. The ‘Desk Ruler’ is a very common type of ruler. People often associate this instrument with the term ‘ruler’ itself. These rulers are typically 12 inches (30 cm) long. They are useful for general purpose tasks. These tasks include math, geometry, and drawing.

Other common types of rulers include:

Plastic rulers: These are lightweight and inexpensive. Schools often use them. They are clear, which helps with schoolwork, drawing, and simple crafts.

Wooden rulers: These classic, solid rulers are strong. People commonly use them for general measuring at home or in workshops. They also work for some craft projects.

Standard rulers (about 30 cm or 12 inches long): This is a very common size. You find them in schools and homes. They are ideal for most school projects, drawing on normal-sized paper, and measuring small items.

Architect’s rulers and engineer’s rulers are specialized types. They feature multiple scales for specific drafting needs. Flexible or bendable rulers can measure curved surfaces. These different types of measuring tools offer versatility.

Materials and Markings

Rulers come in various materials. Each material offers specific advantages.

Material | Advantages |

|---|---|

Plastic | Affordable: Generally the most budget-friendly option. |

Aluminum | Durable: More robust and long-lasting than plastic. |

Stainless Steel | Extremely Durable: Highly resistant to corrosion, rust, and wear. |

Bamboo/Wood | Eco-Friendly: A sustainable and renewable resource. |

Acrylic | Transparent: Allows you to see through the ruler to the drawing surface. |

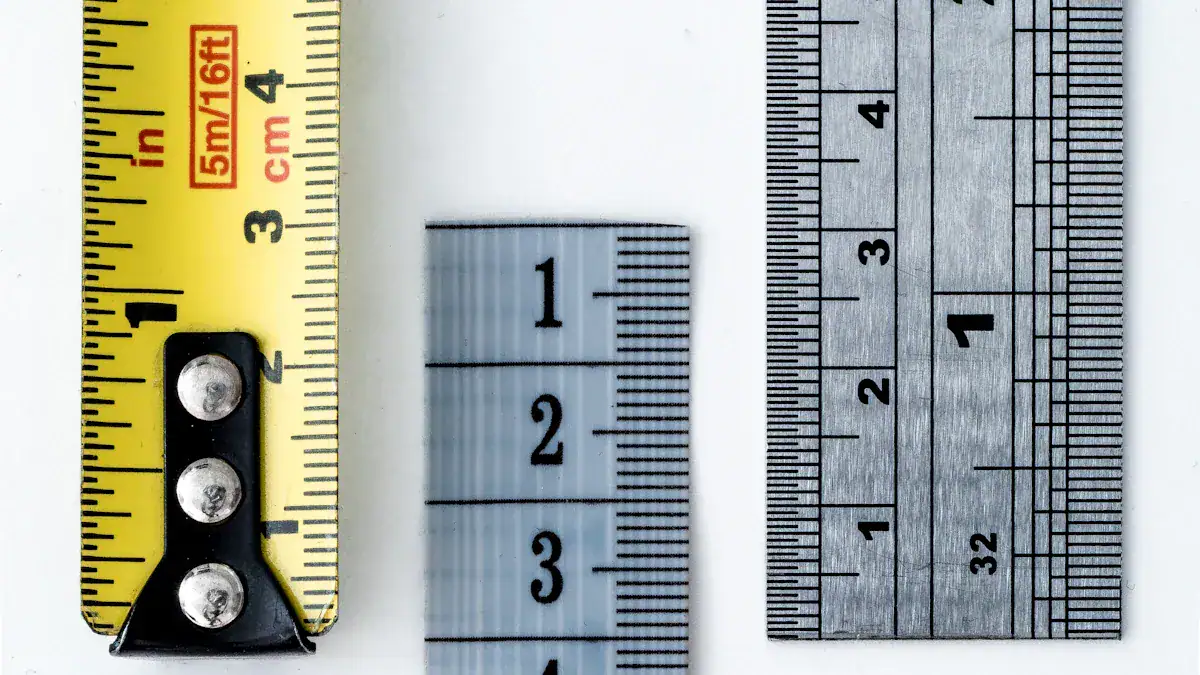

Rulers display various measurement units. The most common are inches, centimeters, and millimeters.

Inch Ruler (U.S.):

It shows inches. Each inch divides into 16 parts.

Markings include: full inches (longest lines), 1/2-inch marks (halfway between inches), 1/4-inch marks, 1/8-inch marks, and 1/16-inch marks (smallest lines).

Metric Ruler (Global):

It shows centimeters (cm) and millimeters (mm).

Markings include: full centimeters (large numbers next to long lines), 1/2-centimeter marks (slightly shorter lines), and millimeter marks (10 millimeters per centimeter).

On inch rulers, the smallest markings can be eighth-inch ticks (1/8″) or sixteenth-inch ticks (1/16″). For metric rulers, the smaller ticks represent millimeters. Ten millimeters make up each centimeter.

Ruler Applications

People use rulers for many tasks. Students use them for schoolwork and art projects. Craftsmen use them for precise cuts and measurements. Architects and engineers rely on them for drafting and design. A measuring ruler is essential for any task requiring straight lines or basic length measurement. These measuring tools are indispensable for accuracy in many professions and hobbies.

Measuring Tapes: Versatility and Reach

What is a Measuring Tape

A measuring tape is a flexible linear measuring tool. It helps determine length or distance, especially over longer spans or around curved objects. Unlike a rigid ruler, a measuring tape can bend and conform to different shapes. This flexibility makes it an indispensable measuring tool for many tasks.

Tape Varieties

Many types of measuring tapes exist, each designed for specific applications. These different types offer unique advantages.

Retractable Tapes: These are common in construction and DIY. They feature a curved metallic ribbon. This ribbon stays stiff when extended. It retracts into a compact case for storage. Many retractable tape measure models include a hook. This hook helps users get accurate inside and outside measurements. Some even have a graphite tip for self-marking.

Sewing Tapes: Tailors and crafters use these flexible tapes. They were originally made from cloth or plastic. Modern versions often use fiberglass for increased durability. Tailor’s tapes are ideal for measuring curved surfaces. They work well for fabric or the human body. They are typically 60 inches long. They have a compact, roll-up design. These flexible tape measures are used for assessing fabric length and width. They also help with body dimensions and sizing for coverings. They are pliable, lightweight, and easily bend around curves for accurate body measurement.

Fiberglass Tapes: These tapes are non-conductive. They are suitable for electrical work or outdoor use where metal tapes might pose a risk. They are also resistant to stretching and moisture.

Steel Tapes: These are durable and precise. People use them for general construction and home projects. They offer reliability for smaller tasks.

Surveyor Tapes: Professionals use these for large spaces. They help survey distances in landscaping or large construction sites.

Digital Tapes: These advanced types of measuring tools can store measurements. They calculate area or volume. Some even connect to smartphones.

Design and Features

Modern measuring tapes come with many features that enhance usability and precision.

Lock Mechanisms: A crucial feature is the ‘spring-click’ or locking mechanism. Alvin J. Fellows patented this in 1868. It allows the tape to be held in place when extended. This feature is vital for users to mark multiple increments within a set distance. This is especially true in construction work. New-generation Control-Lock™ buttons offer precise hold and release.

End Hooks: Most tape measure models have an end hook. This hook provides a secure grip on edges. A Tru-Zero hook design ensures accurate inside and outside readings. Some have a three-rivet end hook with reinforced metal backing.

Blade Design:

Advanced alloy construction provides durability.

Laser-etched measurements offer clear readability.

Dual measurement scales (Metric + Inch) are common.

High-quality steel blades are often coated for wear resistance.

Yellow-coated, rub-resistant blades (19 mm width) are typical.

Blade Armor™ coating on the first 7 cm prevents wear.

Dual-side print allows for efficient reading.

Acrylic blade coating protects against rust and abrasion.

Mylar® coating guards the blade against scratches.

Housing and Ergonomics:

Durable plastic housing provides impact resistance.

Ergonomic designs make the tape measure comfortable to hold.

Weatherproof, non-slip rubberized cases often include a metal clip and lanyard.

Durable ABS plastic cases with ProTouch™ grip offer comfort.

Compact, lightweight bodies enhance portability.

Advanced Features:

LCD digital readouts with mm/inch switchable displays offer convenience.

Some tapes have a standout up to 2.6 meters (8.5 feet). This allows for one-person use.

Removable magnetic hooks and slow-retract windows appear on longer versions.

Direct-reading blade layouts help with internal dimensions.

Chrome-plated metal cases offer wear resistance.

Tape Measure Uses

People use a tape measure across many industries and for various projects.

Construction and Carpentry: Construction workers and carpenters rely heavily on a tape measure. They use it for surveying distances. They also gather room and furniture dimensions. Modern construction tapes often feature magnetic hooks and shock-absorbing ends. Folding measuring sticks, made of rigid sections, offer durability and precision for rough job sites. These are essential types of measuring tools for carpentry.

Tailoring and Sewing: Flexible tape measures are crucial for tailors. They use them for body measurements and fabric cutting.

Plumbing: Plumbers use a tape measure for pipe lengths and fixture placement. These are important types of measuring tools for plumbing.

Home Improvement: Homeowners use a tape measure for DIY projects. This includes hanging pictures, arranging furniture, or installing shelves.

Landscaping and Interior Design: Laser tape measures are used for large-scale projects. They provide pinpoint accuracy for outdoor spaces or room layouts.

A tape measure offers versatility and reach. It handles both long distances and curved surfaces. This makes it a vital measuring tool in many different types of work.

Calipers: Precision Measuring Tools

What are Calipers

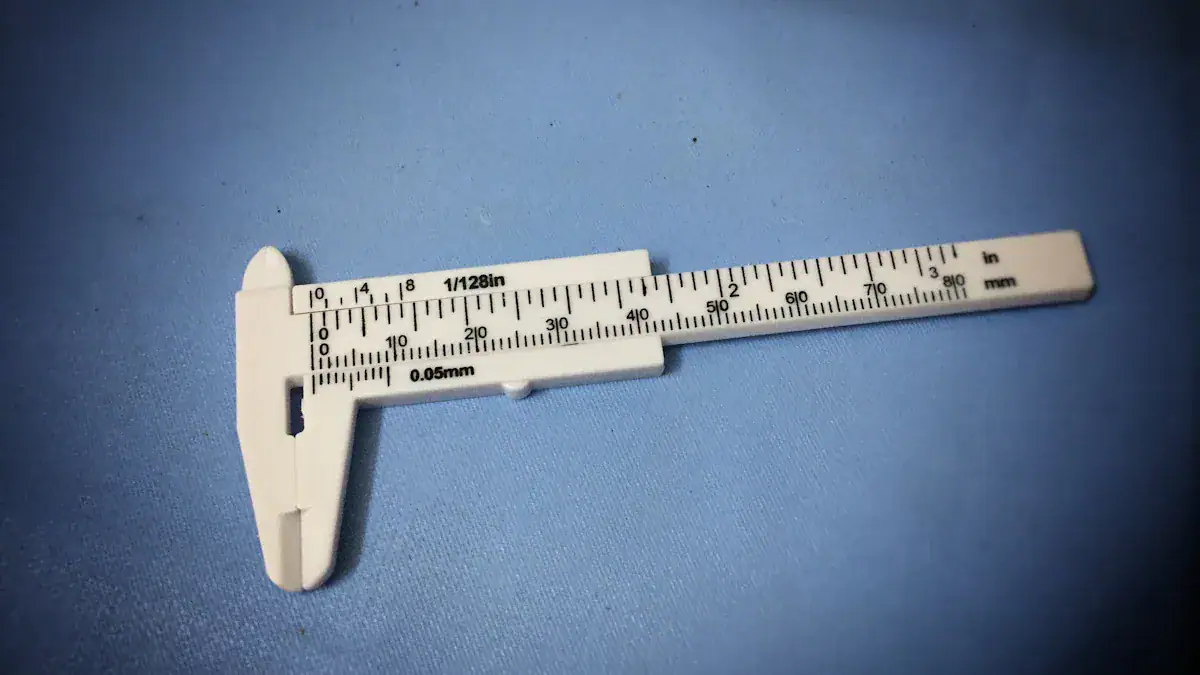

Calipers are specialized measuring tools. They measure distances between two opposite sides of an object. Calipers achieve high precision. They are essential for tasks needing exact dimensions. This makes them important precision measuring tools. A caliper is a versatile measuring tool. They are crucial for measuring distances accurately.

Main Caliper Types

There are three main types of calipers. Each type offers different features for measurement. These types of precision measuring tools include Vernier, dial, and digital calipers. These different types serve various needs.

Vernier Calipers: Vernier calipers are basic ruler calipers. They feature a main scale and a sliding Vernier scale. Users manually adjust their jaws. They read the measurement by aligning lines on both scales. This caliper provides good precision for many tasks.

Dial Calipers: Dial calipers have a dial indicator. This dial shows fractional measurements. They are easier to read than Vernier calipers. A gear and pinion mechanism moves the needle on the dial. This caliper offers quick and accurate readings.

Digital Calipers: Digital calipers feature an electronic display. This display shows measurements digitally. They are the easiest to read among the types. Users can often switch between metric and imperial units. Digital calipers offer high accuracy. Ordinary 6-inch digital calipers have an accuracy of 0.001 inches. They also have a resolution of 0.0005 inches. This means they are reliable for tolerances up to 0.002 inches. Some professional settings limit their use to tolerances no finer than 0.010 inches. This maintains a margin of error and promotes good measurement practices. These types of measuring tools are very popular.

Reading Caliper Measurements

Reading measurements from a caliper requires practice. Each type of caliper has a specific method.

Reading Vernier Caliper Measurements: Vernier calipers require careful observation. Follow these steps to read them:

Holding the Caliper: Use your thumb to slide the jaws open and closed. The locking screw at the top can set a dimension.

Course Reading: Identify the whole inch number and the tenths of an inch from the main scale. For example, if the vernier zero is past the ‘3’ mark after the ‘1’ inch, you have 1.3 inches.

Fine Reading: Observe the vernier scale to find which line aligns exactly with a line on the main scale. This aligned line indicates the thousandths of an inch. Add this value to your course reading. For instance, if the 6th line on the vernier aligns, add 0.006 to your measurement.

Reading Dial Caliper Measurements: Dial calipers are simpler. Read the main scale for whole units. Then, read the dial for the fractional part. The dial directly shows the precise measurement.

Reading Digital Caliper Measurements: Digital calipers are the easiest. The measurement appears directly on the screen.

Caliper Applications

Calipers are vital in many fields. They provide precise measurements.

Engineering: Engineers use calipers for designing parts. They ensure components fit together correctly.

Machining: Machinists use calipers to check the dimensions of machined parts. This ensures quality control.

Quality Control: Inspectors use calipers to verify product specifications. This maintains high standards.

Jewelry Making: Jewelers measure gemstones and settings with calipers. This requires extreme precision.

Automotive: Mechanics use calipers to measure brake rotors and engine components. This ensures proper fit and function.

These types of measuring tools are indispensable for tasks demanding high precision. They are among the most important types of precision measuring tools. Many different types of jobs rely on them.

Selecting the Right Measuring Tools

Choosing the correct measuring tools is crucial for any project. The right tool ensures accuracy and efficiency. Many factors influence this decision. Understanding these factors helps achieve successful outcomes.

Factors for Tool Selection

Many critical factors guide the selection of a measuring device. People must consider the specific needs of their task.

Accuracy and Precision: Different projects demand varying levels of accuracy. Tools must meet the required accuracy. This ensures quality and minimizes errors. This is especially true in fields like aerospace or medical device manufacturing.

Durability: Tools should be made from high-quality materials. They must withstand daily wear, harsh conditions, and repeated calibration. This maintains accuracy over time.

Digital vs. Analog: Digital tools offer quick readings. They are easy to use. They also have features like data recording. This makes them ideal for rapid, precise measurements. Analog tools are simpler and more robust. They are immune to electronic failures. They suit basic measurements and situations prioritizing reliability.

Understanding Measurement Needs: This involves considering the type of measurements required. Examples include dimensional, surface roughness, or temperature. It also includes the desired accuracy and necessary resolution or sensitivity levels. Expected workload, throughput, and regulatory compliance are also part of this.

Ease of Use: The device’s interface must be easy for operators to use. The simplicity and speed of training new users are also important. This helps minimize downtime.

Measuring Range: The instrument must precisely measure the range of process variables needing monitoring.

Maintenance and Calibration: Consider how easy the instrument is to maintain and calibrate. Regular calibration is essential for long-term accuracy and reliability.

Cost: Balance the instrument’s cost with its features, accuracy, and dependability. Avoid cheaper options. They may lack necessary precision and lead to higher long-term expenses.

Precision Requirements

The required measurement precision heavily influences tool choice. Different measuring tools offer varying levels of exactness.

Tool Type | Precision Level |

|---|---|

Micrometers | Highest |

Calipers | Medium |

Rulers/Tape Measures | Lowest |

Micrometers offer the highest precision. They are ideal for diameter measurements. They are used for quality control and verifying tight tolerances. This is especially true for shank or major diameters. Calipers are versatile. They measure outside/inside diameter, length, and depth. Digital calipers provide the easiest reading. They are highly recommended for general industrial use. These are excellent precision measuring tools. Rulers and a tape measure are best for quick, less critical checks. They measure overall length on larger fasteners or approximate measurements. However, they lack the precision for fine details or diameters. Choosing the right tool ensures the necessary precision for the task.

Material and Environment

The material being measured and the working environment also dictate tool selection. A tool must perform reliably under specific conditions.

For example, a metal ruler works well in a dry workshop. A flexible tape measure is better for curved surfaces. For outdoor work, a durable, weather-resistant tape measure is essential. Fiberglass tapes are non-conductive. This makes them suitable types of measuring tools for electrical work. They are also resistant to stretching and moisture. This makes them ideal for outdoor use. In contrast, metal tapes might pose a risk in electrical work. The tool should withstand challenging conditions. These include high temperatures, humidity, or corrosive materials. This may require extra protection. Therefore, consider the environment when selecting measuring tools.

Tools for Workshops and Projects

A well-equipped home workshop needs a specific measuring tools list. These tools help with various projects.

Angle Locators and Protractors: These capture and measure angles. They ensure level and plumb surfaces. Some models offer digital displays.

Calipers: These versatile tools measure various dimensions. Examples include pipe diameters, hole depths, and object thickness. They come in Vernier, dial, and digital types.

Plumb Bobs: This weighted tool has a point. People use it with a string to determine vertical straightness.

Pencil Compass: This is essential for drawing perfect circles. It features a point for material insertion and a pencil for marking.

For carpentry, a sturdy ruler and a reliable tape measure are fundamental types of measuring tools for carpentry. They help measure boards and mark cuts. For plumbing, a tape measure and a caliper are crucial. They measure pipe lengths and diameters. These are important types of measuring tools for plumbing. For general DIY, a basic measuring tools list includes a ruler, a tape measure, and a small square. These are common types of measuring tools for workshops. For tasks requiring high accuracy, digital calipers are excellent precision measuring tools. They provide quick and easy readings. These different types of measuring tools help ensure accuracy in any project.

Rulers, measuring tapes, and calipers are essential measuring tools. Rulers offer basic linear measurement. Measuring tapes provide versatility for longer distances and curves. Calipers deliver high precision for detailed work. Selecting the correct tool is crucial for achieving precision and efficiency in any project. Readers should apply this knowledge to their future endeavors. They can also explore advanced measurement techniques.

FAQ

What is the primary difference between a ruler and a measuring tape?

A ruler is a rigid, straight tool for measuring short, flat distances and drawing straight lines. A measuring tape is flexible. It measures longer distances and curved surfaces. Its flexibility allows it to conform to various shapes.

When should someone choose calipers over a ruler or tape measure?

People choose calipers for high-precision measurements. They are ideal for tasks requiring exact dimensions, such as measuring the diameter of a pipe or the thickness of a small part. Rulers and tapes offer less precision.

Can digital calipers measure both metric and imperial units?

Yes, most digital calipers offer the ability to switch between metric (millimeters) and imperial (inches) units. This feature makes them very versatile for different projects and international standards.

What are the advantages of a fiberglass measuring tape?

Fiberglass measuring tapes are non-conductive. This makes them safe for electrical work. They also resist stretching and moisture. These qualities make them suitable for outdoor use and challenging environments.

Why do some measuring tapes have a “Tru-Zero” hook?

A “Tru-Zero” hook ensures accurate inside and outside measurements. It slides slightly to account for the hook’s thickness. This provides a precise starting point whether pushing against a surface or hooking onto an edge.