You want to know the main types of paint sprayers. They are airless paint sprayers, HVLP paint sprayers, and compressor paint sprayers. These tools offer significant advantages over brushes and rollers. For example, using a house paint sprayer for DIY projects can be up to 15 times faster. One painting company reports that they utilize paint sprayers for approximately 75% of their projects, consistently achieving positive outcomes. You get a smoother, more even finish quickly. This guide will help you understand these different types of paint sprayers to pick the best one for your next project.

Key Takeaways

Choose the right paint sprayer for your job. Airless sprayers work best for big areas. HVLP sprayers are good for detailed work. Compressor sprayers are for special tasks like car painting.

HVLP sprayers give the smoothest finish. They use less paint and have less mess. This makes them great for furniture and cabinets.

Always prepare your surface before painting. Clean, sand, and prime it. This helps the paint stick well and look smooth.

Thin your paint if needed. HVLP and compressor sprayers often need thinner paint. Check your paint and sprayer instructions for the right mix.

Clean your paint sprayer right after each use. This keeps it working well. Also, wear safety gear like masks and gloves to protect yourself.

Main Types of Paint Sprayers

Overview

You will encounter three primary types of paint sprayers when planning your next project. These include airless paint sprayers, HVLP paint sprayers, and compressor paint sprayers. Each system operates on a distinct principle. They also excel at different kinds of painting jobs. Knowing these core differences is crucial. It empowers you to select the most effective tool. This choice directly impacts your project’s speed, finish quality, and overall success.

Airless paint sprayers work by using a powerful pump. This pump pressurizes the paint to very high levels. It then forces the paint through a tiny opening in the spray tip. This high pressure atomizes the paint into a fine mist. You can cover large surfaces very quickly with these tools. They are ideal for exterior walls, interior rooms, and large fences. Their speed makes them a favorite for big jobs.

HVLP paint sprayers, which stands for High Volume Low Pressure, operate differently. They use a large volume of air at a much lower pressure. This gentle air stream carries the paint to the surface. You get a very controlled and soft spray pattern. This method significantly reduces overspray. It also produces an exceptionally smooth and fine finish. These sprayers are perfect for detailed work. Consider them for cabinets, furniture, trim, or even automotive finishes.

Compressor paint sprayers, also known as conventional spray guns, require an external air compressor. The compressor supplies air to the gun. This air mixes with the paint, creating a finely atomized spray. These systems offer great flexibility. You can adjust air pressure and fluid flow. This allows for a wide range of finishes and paint types. They are often chosen for automotive applications, intricate artwork, or specific industrial coatings.

You will explore each of these paint sprayers in greater detail. This will help you understand their unique mechanisms. You will also learn their best applications. This knowledge ensures you pick the perfect sprayer. You can achieve professional results on any painting task.

Airless Paint Sprayers

Mechanism

Airless paint sprayers work by using extreme pressure. You do not use air to atomize the paint. Instead, a powerful pump forces paint through a very small tip. This high pressure breaks the paint into tiny droplets. It creates a fine spray. The pressure can vary greatly. For example, you might use 800-1100 psi for lacquers. Stains often need 1200-1800 psi. Latex coatings typically require over 2000 psi. Some airless paint sprayers can reach up to 4000 psi.

Applications

You will find airless paint sprayers excellent for large projects. They cover big areas quickly. Many professionals use them for home exteriors, fences, and decks. You can also use them for interior walls and ceilings. They are great for unfinished rooms. Beyond typical painting, these paint sprayers handle specialized tasks. This includes mortar application, roof coating, and even pavement marking.

Advantages

These paint sprayers offer significant speed. You can finish large jobs much faster than with brushes or rollers. They also provide a smooth, even finish. This finish looks professional. Airless sprayers can handle thicker paints. You do not always need to thin your paint as much.

Disadvantages

Airless systems can create more overspray. This means paint particles can travel further. You will need to use more masking and drop cloths. They also use more paint compared to other types of paint sprayers. This can increase your material costs.

Paint Compatibility

Airless paint sprayers work well with many paint types. You can use latex paints, oil-based paints, and enamel paints. Many users thin their paint with water for latex or paint thinner for oil-based products. This helps the sprayer work more easily. Specific paints like Benjamin Moore Advance Interior Satin Paint and Sherwin-Williams Emerald Urethane Trim Enamel are good choices. Behr Premium Enamel Satin Cabinet & Trim Paint also works well.

HVLP Paint Sprayers

Mechanism

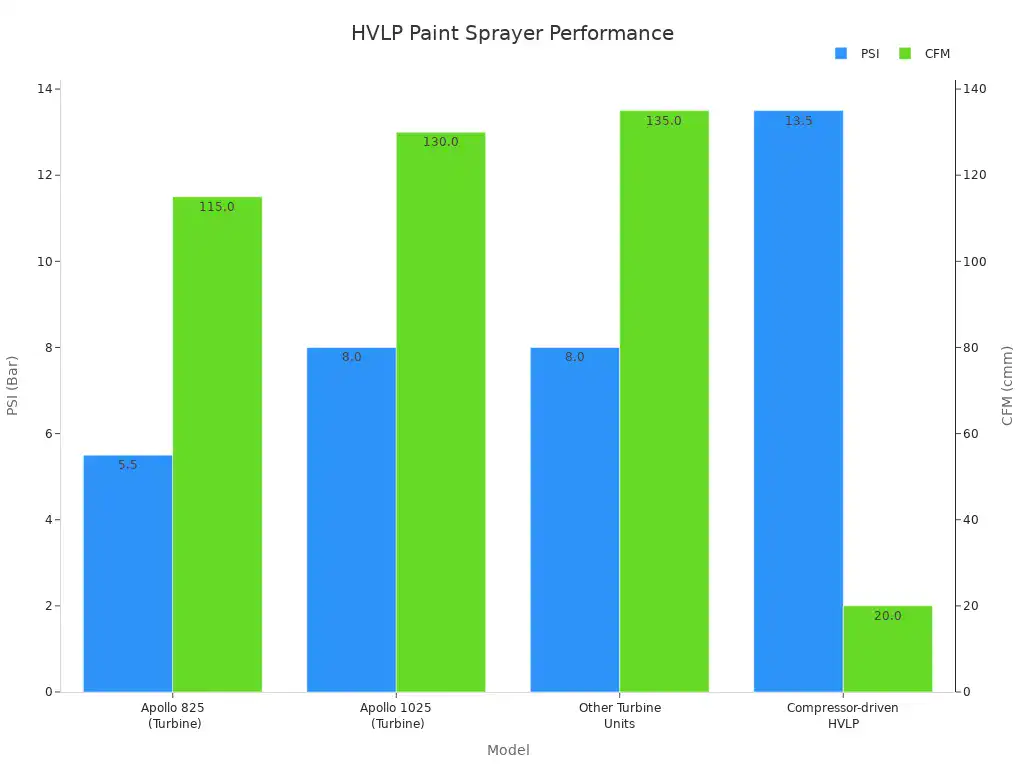

HVLP paint sprayers operate differently from airless models. HVLP stands for High Volume Low Pressure. These paint sprayers use a large amount of air. They deliver this air at a much lower pressure. This creates a soft, controlled spray. You can find HVLP systems driven by a turbine or an external air compressor. The recommended air pressure for HVLP paint sprayers is typically around 6-10 PSI. Turbine units often provide 5-11.5 PSI with over 65 CFM. This table shows typical outputs:

System Type | Air Pressure (PSI) | Air Volume (CFM) |

|---|---|---|

HVLP (Turbine Unit) | 5-11.5 | 65+ |

Conventional Spray Guns | 20-50 | Under 30 |

Applications

You will find HVLP paint sprayers excel at detailed work. They are perfect for projects needing a fine finish. Consider them for:

Furniture painting

Cabinets

Automotive finishes

Smaller objects and complex surfaces

Intricate work requiring maximum accuracy and control

Woodworking applications

These paint sprayers handle various coatings. This includes lacquers, stains, and even some wall emulsion paints.

Advantages

HVLP paint sprayers give you a very smooth finish. The low pressure means less overspray. This saves paint. You also get more control over where the paint goes. This makes them ideal for precision jobs.

Disadvantages

These paint sprayers work slower than airless models. They cover smaller areas at a time. You often need to thin your paint more. This adds an extra step to your preparation.

Paint Compatibility

HVLP paint sprayers require thinner paints. You might need to thin paint up to 20%. Decorative paints often need thinning for HVLP systems. This includes emulsions, eggshells, primers, undercoats, satins, and glosses. For latex paints, water is the main thinning agent. Always check the manufacturer’s guidelines. This ensures you get the correct thinning ratio for your specific paint.

Compressor Paint Sprayers

Mechanism

You use an external air compressor with compressor paint sprayers. These are also known as pneumatic air sprayers. The compressor sends compressed air to the spray gun. This air mixes with the paint inside the gun. This creates a fine mist. This process is called atomization. The air pressure and volume are important. Different setups need different air flow. For example, a Binks gun with a C1 HVLP cap needs at least 6.4 CFM. CFM is more important than pressure for good spraying.

Paint Sprayer/Compressor | CFM @ PSI | Notes |

|---|---|---|

Binks gun with C1 HVLP cap | 6.4 CFM minimum | CFM is more important than pressure for spraying. |

User’s compressor | 9 CFM @ 40 PSI, 7.5 CFM @ 90 PSI | Recommends 7-9 CFM @ 40 PSI for cushion when gun is 4-6 CFM. |

Air Assisted Airless (Kremlin Airmix) | ~2 CFM @ 40 PSI | Requires very little air. |

Eastwood 30 Gallon Air Compressor | 5.7 CFM @ 90 PSI | |

Chicago Pneumatic 20 Gallon Air Compressor | 7.1 CFM maximum @ 90 PSI | Considered bare minimum for Binks gun with C1 HVLP cap. |

Applications

You will find compressor paint sprayers in many professional settings. They are essential in automotive body shops. For example, the EMAX ESP10V120V1 compressor is good for body shop spray applications. It provides power for use throughout business hours. These systems handle professional auto painting. They also reduce moisture to prevent paint defects. You can use these paint sprayers for various projects:

Furniture Painting: Use acrylic paint. Nozzle sizes are typically 1.3 – 1.8 mm.

Automotive Painting (Base Coat): Apply car base coats. Use automotive paint. Nozzle sizes are 1.2 – 1.4 mm.

Crafting Projects: Do detailed crafting. Use acrylic paint. A smaller nozzle (0.8 – 1.2 mm) and lower PSI (15-20) work best.

House Interiors/Walls: Paint house interiors and walls. You need specific techniques for even coverage.

Advantages

These paint sprayers offer great versatility. You can adjust air pressure and fluid flow. This allows for many finishes. They provide fine atomization for specific paints. This fine mist helps you achieve very smooth results. You can also use them for a wide range of materials.

Disadvantages

You need a separate air compressor. This adds to the initial cost and setup time. They can also create more overspray than HVLP models. This means you might use more paint. You also need more masking.

Paint Compatibility

Compressor paint sprayers work well with low volume paints. They are good for paints needing high atomization. Car finishes are a common use.

Sprayer Comparison

Project Suitability

You need to match your paint sprayer to your project. Airless paint sprayers are excellent for big jobs. You can paint the exterior of a house quickly. Graco’s Pro Series are for professionals. These are perfect for property maintenance or remodeling. They handle large paint sprayer projects with ease. HVLP sprayers are better for smaller, detailed work. Think about furniture or cabinets. Compressor paint sprayers work well for automotive finishes. They also suit other specialized tasks.

Finish Quality

The finish quality varies among the types of paint sprayers. HVLP paint sprayers consistently give you the smoothest finish. They are highly recommended for cabinet work. HVLP systems offer precision. They also reduce overspray. This is important for intricate jobs like cabinets. A detailed finish nozzle helps create a professional look. Airless sprayers provide a good, even finish. This is great for large surfaces. Compressor sprayers offer fine atomization. This helps you achieve very smooth results for specific paints.

Ease of Use

Each paint sprayer type has a different learning curve. Airless sprayers are powerful. They require some practice to control. Setup is usually quick. HVLP sprayers are more forgiving. Their lower pressure makes them easier to handle. You often need to thin your paint. This adds an extra step. Compressor sprayers need a separate air compressor. You manage more components. This can make setup more complex.

Cost Factors

Consider the cost when choosing your sprayer. Airless sprayers often have a higher initial cost. They save time on large jobs. This can make them cost-effective in the long run. HVLP sprayers are usually in the mid-range for cost. They use less paint. This can save you money on materials. Compressor sprayers require buying both the gun and a compressor. The total cost can vary widely.

Efficiency and Overspray

Efficiency and overspray are important for paint usage. HVLP sprayers produce less overspray. They have a much greater transfer rate. More paint goes onto your surface. They operate at lower pressure, like 4.5 PSI. This high volume, low pressure reduces waste. Airless sprayers have higher wastage. They create more overspray. They operate at high pressure, like 2200 PSI. This leads to more overspray. Compressor sprayers can also have significant overspray. This depends on your settings.

Feature | HVLP Sprayers | Airless Sprayers |

|---|---|---|

Waste/Overspray | Produce less overspray, leading to a much greater transfer rate of coating to the surface. | Have higher wastage due to more overspray. |

Pressure | Operate at much lower pressure (e.g., 4.5 PSI), resulting in high volume, low pressure, and minimal overspray. | Operate at high pressure (e.g., 2200 PSI), leading to high volume and more overspray. |

Paint Distribution | Can control the equal distribution of paint with a larger volume and lower air pressure, reducing paint waste. | (Not specified in terms of controlled distribution or waste reduction from this aspect) |

Pre-Spray Essentials

Before you start spraying, you must prepare. Proper preparation ensures a smooth finish. It also keeps your equipment working well. Following these steps helps you get the best results.

Surface Preparation

You must prepare your surface for paint. First, clean it. Remove all dust, dirt, and grease. Use cleaning agents to make sure paint sticks well. Next, sand rough spots. This removes old paint. It creates a flat base. Sanding also helps paint stick better. This prevents bubbles and unevenness. Then, fill any cracks and holes. Use fillers to patch imperfections. Sand these areas again. This blends the repairs for an even surface. Finally, apply primer. Primer seals the surface. It gives a uniform base. Primer also makes colors brighter. It improves paint durability. You must remove surface contaminants. Dirt, dust, and oil create barriers. These barriers stop paint from sticking. Methods like laser cleaning or chemical cleaning help. You can also increase surface roughness. Sanding or chemical etching helps coatings stick better. If you use abrasives, remove all dust. Dust affects bond quality. Rinse off any chemical residues. These residues can interfere with your paint.

Paint Thinning

You might need to thin your paint. This helps it flow smoothly through your paint sprayers. Viscosity is how thick your paint is. Krebs Stormer viscometers measure paint consistency. They use Krebs Units (KU). Higher KU values mean thicker paint. These viscometers also show centipoise (cP) and grams (gm). A typical range is 40-141 KU. This equals 27-5274 cP. Other methods measure viscosity too. These include Poise, Gardner-Holt Bubble, and Efflux methods. Always check your paint sprayer manual. It tells you the right thinning ratio.

Cleaning and Care

Cleaning your paint sprayers is very important. Clean them right after each use. For latex paint, disassemble the spray gun. Clean it with hot water and dish soap. Fill the canister with soap and water. Spray it through the gun. Use brushes to clean the insides. When you finish cleaning, apply special lubricant. If you switch from latex to solvent-based paint, flush the system completely. Use water to remove all latex paint. Residual latex paint can react with solvents. This can plug up your system. Clean the spray guard and tip thoroughly. Use warm water. A soft bristle brush helps remove dried paint. You can also use denatured alcohol for latex paint. Run it through the system. Let it sit for 30 minutes. Then flush with hot water. You might need to repeat this.

Safety Guidelines

Safety is crucial when you use paint sprayers. Always wear personal protective equipment (PPE). You need respiratory protection. Respirators protect your lungs from mists and fumes. Full-face respirators filter out paint particles. They must fit properly. Wear eye and face protection. Safety glasses and face shields prevent irritation. They stop paint splatters. Use hand protection. Nitrile or chemical-resistant gloves protect your skin. Wear foot protection. Chemical-resistant boots protect against toxic paints. Shoe covers protect your shoes. Wear full-body protective clothing. Suits with hoods and elastic cuffs prevent skin contact. Earplugs are necessary for loud equipment. Spray socks or hoods protect your head and neck.

You now understand the different types of paint sprayers. Airless models excel at large jobs. HVLP paint sprayers give fine finishes. Compressor systems suit specialized tasks. The best choice for you depends on your project. Consider the finish you want and your skill level. Think about your specific needs to pick the right tool.

FAQ

### Which paint sprayer is best for beginners?

You will find HVLP paint sprayers generally easier for beginners. They offer more control. Their lower pressure reduces overspray. This makes them more forgiving. You can achieve good results with less practice.

### Do I always need to thin paint for spraying?

You often need to thin paint for HVLP and compressor sprayers. This helps the paint flow smoothly. Airless sprayers can handle thicker paints. Always check your paint and sprayer manuals for specific thinning instructions.

### Can I use any type of paint in any sprayer?

No, you cannot use all paints in every sprayer. Airless sprayers work well with thick paints like latex. HVLP sprayers require thinner paints. Compressor sprayers suit specific low-volume, high-atomization paints. Always match the paint to your sprayer type.

### What is overspray, and how can I reduce it?

Overspray refers to paint particles that miss your target surface. HVLP sprayers produce less overspray due to their low pressure. You can reduce overspray by:

Using the correct sprayer for your project.

Adjusting pressure settings.

Maintaining proper spray distance.

Masking surrounding areas thoroughly.

Tip: Always test your spray pattern on scrap material before painting your main project.