A stable, durable workbench is the backbone of any workshop. You gain immense satisfaction and save money when you build your own workbench. This guide provides detailed workbench plans, material insights, and construction tips. You will create a sturdy heavy duty workbench. This robust foundation supports all your future projects.

Key Takeaways

Building your own heavy-duty workbench saves money. It also gives you a custom design. This workbench will fit your specific needs.

A sturdy workbench is important. It provides stability for precise work. It also handles heavy tasks without problems.

Plan your workbench carefully. Consider its size and the materials you will use. Wood and steel are common choices for strength.

You can choose from different workbench plans. Options include 2×4 wood, plywood, or steel frame designs. Pick one that fits your skill and budget.

Enhance your workbench with useful features. Add vises for holding items. Include storage solutions and casters for easy movement.

Why Build a Sturdy Workbench

You gain many advantages when you build a sturdy workbench. This essential piece of equipment improves your work and saves you money.

Stability for Precision

A stable workbench is crucial for accurate work. When your workbench does not wobble, you can make precise cuts and measurements. This stability prevents errors. It ensures your projects turn out exactly as you plan. You achieve better results with a solid foundation.

Durability for Heavy Tasks

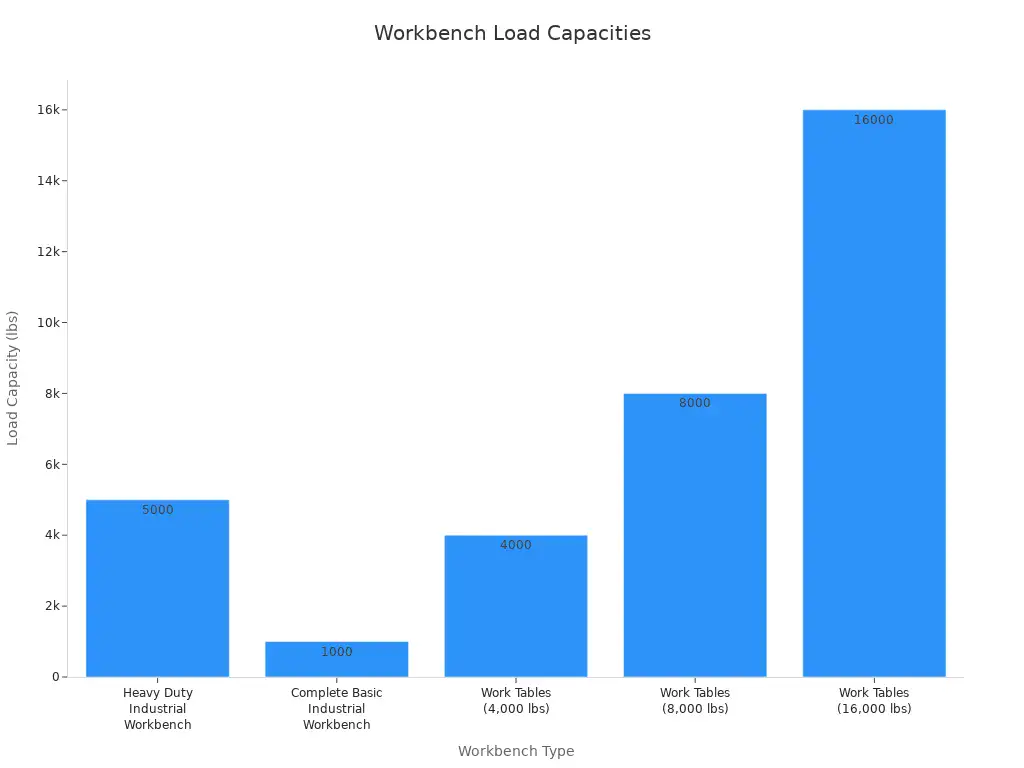

You need a workbench that can handle significant weight. A durable workbench supports heavy tools and materials without failing. This strength is vital for many workshop tasks. Commercially, some workbenches offer impressive capacities:

Model LHD Lab Heavy Duty Workbench (QS): 5,000 pound capacity with evenly distributed weight.

Model ELHD Ergoline Heavy Duty Crank Adjustable Workbench: 750 pound capacity.

An Extra Heavy Duty Welded Steel Workbench offers a substantial 15,000 lb. capacity. You can see how capacities vary:

Workbench Type | Load Capacity |

|---|---|

Heavy Duty Industrial Workbench | 5,000 lbs |

Complete Basic Industrial Workbench | 1,000 lbs |

Work Tables | 4,000 lbs, 8,000 lbs, 16,000 lbs |

This shows you need a heavy duty workbench that matches your heaviest tasks.

Customization for Your Space

You can design a workbench that fits your exact needs. A custom workbench maximizes your workshop space. It also improves how you work.

It keeps your workspace safe and organized.

Adjustable height mechanisms reduce fatigue.

Mobility features like casters allow easy rearrangement.

Integrated storage keeps tools organized and within reach.

Customizable legs match your height and tasks.

You choose the best function, style, and durability.

Cost Savings Over Buying

Building your own workbench saves you money. You often spend less on materials than you would on a retail workbench. This allows you to get a higher quality bench for a lower price.

Workbench Type | Cost Range (USD) | Notes |

|---|---|---|

DIY Workbench | $100 – $150 | Basic, sturdy, and functional |

$200 – $400 | Good value, can rival $1500 retail benches | |

Retail Workbench | $275 | Low-quality, cheap vises, wimpy legs |

$1300 | Quality construction, good vises, some storage |

You get a strong, custom workbench without the high retail price.

Planning Your Heavy-Duty Workbench

You begin your project by planning your heavy duty workbench. This initial step guides your choices for materials and design. You will make decisions about size, strength, and the tools you need.

Workbench Dimensions

First, consider the space you have. Think about the projects you will do. You need a workbench that fits your area and supports your work. Here are some common dimensions for different activities:

Workbench Model | Work Surface Dimensions (L x W x H) | Total Dimensions (L x W x H) | Ideal Activities |

|---|---|---|---|

Dash-Board | 92” x 23.75” x .5” | 92.56” x 24.41” x 35.5” | Large-scale woodworking, furniture making, extensive crafting, projects requiring spreading out materials or multiple tools |

Dash-Board ShortCut | N/A | 46.75” x 24.5” x 35.5” | Smaller spaces, DIY home projects, small-scale woodworking, crafting, portable station for on-site work |

You can choose a size that works best for you.

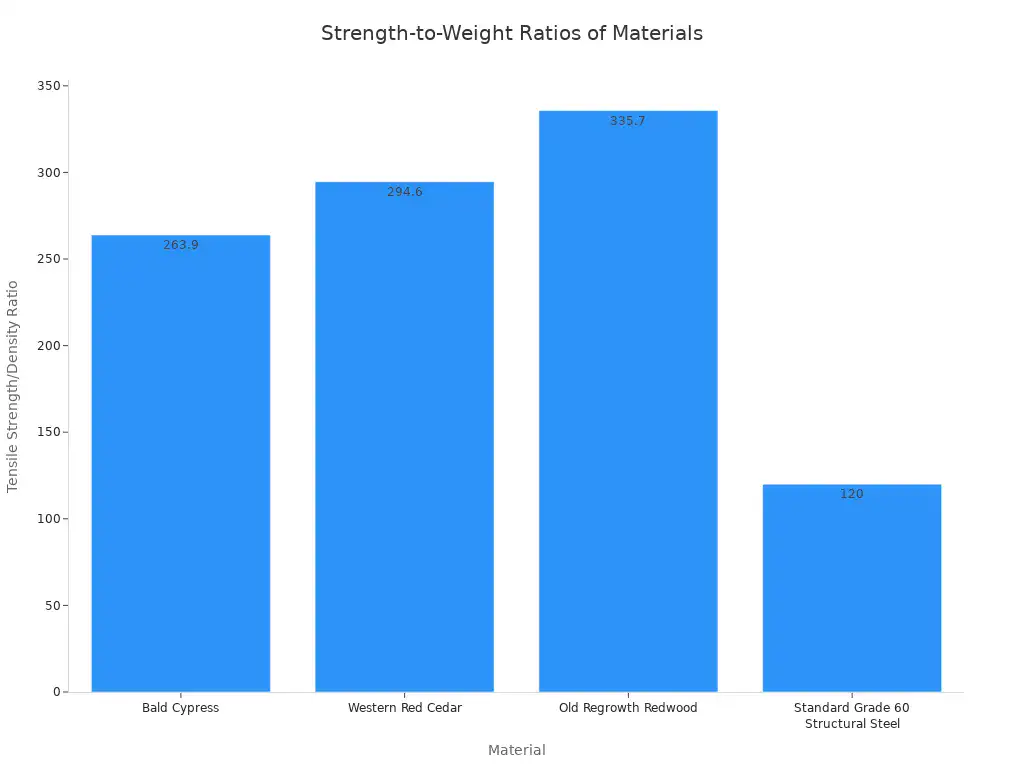

Material Choices: Wood vs. Steel

You have options for your workbench materials. Wood and steel are popular choices. Wood, like 2x4s, 2x6s, and plywood, is easy to work with. Steel offers great strength. You can compare their strength-to-density ratios:

Material | Tensile Strength/Density Ratio |

|---|---|

Bald Cypress | 263.9 |

Western Red Cedar | 294.6 |

Old Regrowth Redwood | 335.7 |

Standard Grade 60 Structural Steel | 120 |

Cold-formed steel framing has a strength-to-weight ratio that often exceeds wood. It provides excellent performance while remaining lightweight.

Weight Capacity Needs

Your workbench must hold the weight of your tools and projects. Different structural elements contribute to its strength.

Heavy Duty Construction: This design handles high weight loads and frequent use. It often uses heavy-gauge steel or other strong materials.

Extra Heavy Duty Construction: This is for very demanding tasks. It uses 12 gauge steel, is fully welded, and has 3” square legs.

Standard Construction: This is for lighter use. It typically uses 16 gauge steel and 2” square legs.

Consider these specifications for weight capacity:

Structural Element | Specification | Weight Capacity (PSF/lbs) | Notes |

|---|---|---|---|

Frame Gauge | 12-gauge steel | 550–700 PSF | |

Frame Gauge | 16-gauge steel | 350–450 PSF | |

Frame Gauge | 10-gauge steel | 3,500 lbs | 30% more strength than 12-gauge, 0.134 inches thick |

Leg Design | Triangulated with cross-bracing | 40% improved weight distribution | Over straight-leg designs |

Essential Tools and Fasteners

You do not need many specialized tools to build a sturdy workbench. Basic tools will get the job done.

Drill/driver

Impact driver (a drill/driver can also work)

Metal drill bit (if you use reinforcing straps)

Miter saw (a hand saw or circular saw can cut lumber)

Jigsaw (a hand saw is an alternative)

You will also need appropriate fasteners like screws or bolts. Choose fasteners strong enough for your chosen materials.

Choosing Your Heavy-Duty Workbench Plan

You have several excellent options for your heavy duty workbench. Each plan offers different advantages. You can choose the best one for your skill level, budget, and workshop needs. Remember, detailed cut lists and step-by-step assembly instructions will be available for each plan.

Classic 2×4 Workbench

The classic 2×4 workbench is a popular choice. It is excellent for beginners. You can build a very sturdy and effective workbench using 2x4s. These materials are readily available. Many builders report completing these benches for a low cost, often under $250, with some even as low as $100. You can finish this project in a short amount of time, usually over a weekend.

Workbenches made with 2x4s are known for being very heavy and stable. This stability makes them perfect for hand tool work. They provide good service for many years. Even beginners can create a functional workbench without spending a lot of money or using complex techniques. One user noted their 2×4 bench remained flat and sturdy after several years of use and abuse. You can reinforce this design with cross-bracing between the legs. This adds extra rigidity. Gussets in the corners also prevent racking.

Plywood Workbench Design

A plywood workbench design offers a smooth, solid work surface. This design is versatile. You can create a very strong structure using layers of plywood. This makes it suitable for various tasks. Plywood is stable and resists warping. You can use thicker plywood for the top to increase durability.

This design often uses plywood for both the top and the structural elements. You can cut plywood precisely. This allows for tight-fitting joints. You can add reinforcement by laminating multiple layers of plywood for the top. This creates an incredibly thick and durable surface. Cross-bracing made from plywood strips can also strengthen the base. You can also use gussets cut from plywood to reinforce corners.

Steel Frame Workbench Hybrid

A steel frame workbench hybrid combines the strength of steel with the workability of wood. This design offers maximum strength and durability. Steel provides exceptional structural integrity. You can build the frame from steel. Then, you can add a wooden top and shelves.

Steel offers many structural advantages. It does not expand or contract with moisture changes. This prevents warping, splitting, cracking, or creeping. Steel has a very high tensile strength. It boasts the highest strength-to-weight ratio among structural framing materials. This can be up to seven times greater than dimensional lumber when formed into C-shapes. Steel is also non-combustible. Its melting point is around 2,700 degrees Fahrenheit. This is much higher than typical building fire temperatures. Steel framing resists corrosion, mold, and vermin. This contributes to its extended lifespan and stability.

You can attach wood components to a steel frame effectively. Self-drilling fasteners with special wings are common. These wings create a slightly wider hole than the thread. This accommodates wood swelling or shrinkage. The winged tip snaps off when it hits the steel. This allows the thread to fasten securely. Proper wing thickness is important. You can also use pocket hole screws. These go through holes in the steel frame to attach a wooden worktop. You can also use them through holes in bottom braces or legs to secure wooden pieces.

Quick and Budget-Friendly Builds

You can build a functional workbench quickly and affordably. These options are perfect if you need a workspace fast or have a limited budget. Some designs allow you to build a workbench in under two hours. Other plans, like the “1 Hour Workbench,” show how fast you can get started.

You can build a sturdy workbench for under $150. For example, you can use Southern Yellow Pine. Seven 2x6x12s, three 2x8x8s, and two 2x4x8s cost under $150 as of October 2022. Techniques include prepping boards, assembling the top, building the base, and attaching the top. Another option uses fifteen 8-foot-long 2x4s and one sheet of 1/2-inch plywood. This can cost between $51 and $100. You cut parts using diagrams. Then, you screw the framing together with 3-inch screws or nail it with 3-inch nails. You screw the plywood down with 1-5/8-inch screws. These builds use minimal tools. You can often complete them in a few hours or over a weekend.

Enhancing Your Workbench

You can make your heavy-duty workbench even more functional. These enhancements improve efficiency and protect your investment.

Vises and Dog Holes

Vises are essential tools for holding your work. You typically install a front vise at the left corner of your workbench’s long edge. This vise holds drawer sides upright for dovetail cutting. It also secures boards edge-up for hand planing. Many front vises include a pop-up dog on the outer jaw. This holds stock flat. An end vise sits at one end of the workbench. It holds material flat on the bench surface. It secures material between dogs on the vise jaw and dogs in the workbench surface. Common front vises feature cast-iron jaws and a steel screw. They use steel rods for jaw alignment. End vises also use a screw-and-rod design. You add a wooden jaw to these mechanisms.

Integrated Storage Solutions

Smart storage keeps your workspace tidy. Metal bin shelving offers assigned locations for tools. These shelves hold at least 800 lbs. You can adjust them for flexible storage. Modular drawer cabinets integrate into your workbench. They store personal items or extra tools. You can add integrated power strips along the back and sides. These provide easy power access. Cord management tools keep cables off the floor. Dedicated charging stations organize your cordless tool batteries. Slatwall above the workbench hangs frequently used tools. Drawer organizers use foam cutouts and dividers. Wall-mounted shelving stores bulky items.

Adding Mobility with Casters

Casters let you move your workbench easily. Locking casters have built-in brakes. They prevent rolling when you work. Swivel casters offer 360-degree rotation. This helps you navigate tight spaces. Rigid casters provide stability for moving heavy loads in a straight line. You often combine them with swivel casters. For heavy-duty workbenches, choose casters with over 2000 lbs. capacity. Polyurethane or steel casters handle heavy loads and rough floors well.

Workbench Top Protection

Protecting your workbench top extends its life. Different materials offer various benefits:

Material | Durability/Protection Features |

|---|---|

Rubber Mats | Excellent for impact absorption, chemical resistance, non-slip surface. |

Silicone Mats | Superior heat resistance, soft surface for delicate items, non-stick. |

Polypropylene Sheets | Extremely durable, resistant to cuts, chemicals, and abrasions. |

HDPE Sheets | Good balance of durability, chemical resistance, and impact strength. |

Plywood/MDF Overlays | Sacrificial layer, easily replaceable, cost-effective. |

Steel/Aluminum Plates | Highest protection against impacts, heat, and sharp objects. |

Long-Term Workbench Maintenance

Regular maintenance keeps your workbench in top condition. Lubricate moving components like drawer slides and vice mechanisms. Use machine oil or silicone lubricant. Inspect for damage and wear regularly. Replace worn parts quickly. Apply rust-resistant coatings to metal surfaces. Use rust inhibitors to prevent corrosion. Protect your workbench surface. Use cutting mats. Avoid excessive weight. Utilize protective coverings.

You now understand the significant benefits of your custom-built, heavy duty workbench. Embark on this rewarding DIY project. Your effort creates a cornerstone for all future workshop endeavors. With these plans and guidance, you can build a sturdy workbench and achieve a professional-grade, sturdy workspace. A robust workbench increases your capability and efficiency as a DIYer or craftsman in your workshop.

FAQ

What is the best wood for a workbench top?

You can use several types of wood. Maple, birch, or oak are very durable. Plywood is also a good choice. Laminate multiple layers for extra strength. Choose a wood that resists dents and scratches. This protects your work surface.

What tools do I need to build a heavy-duty workbench?

You need basic tools. A circular saw or miter saw cuts lumber. A drill/driver fastens parts. A tape measure and square ensure accuracy. Clamps hold pieces while you work. You do not need many specialized tools for your workshop.

What is the ideal height for a workbench?

The ideal height depends on you. Stand with your arms at your sides. Your knuckles should be about workbench height. This prevents back strain. Most workbenches are 34 to 38 inches tall. Adjust it for your comfort.

What are the benefits of adding casters to my workbench?

Casters make your workbench mobile. You can move it for cleaning. You can also rearrange your workshop easily. Locking casters keep it stable when you work. Choose heavy-duty casters for a sturdy bench.